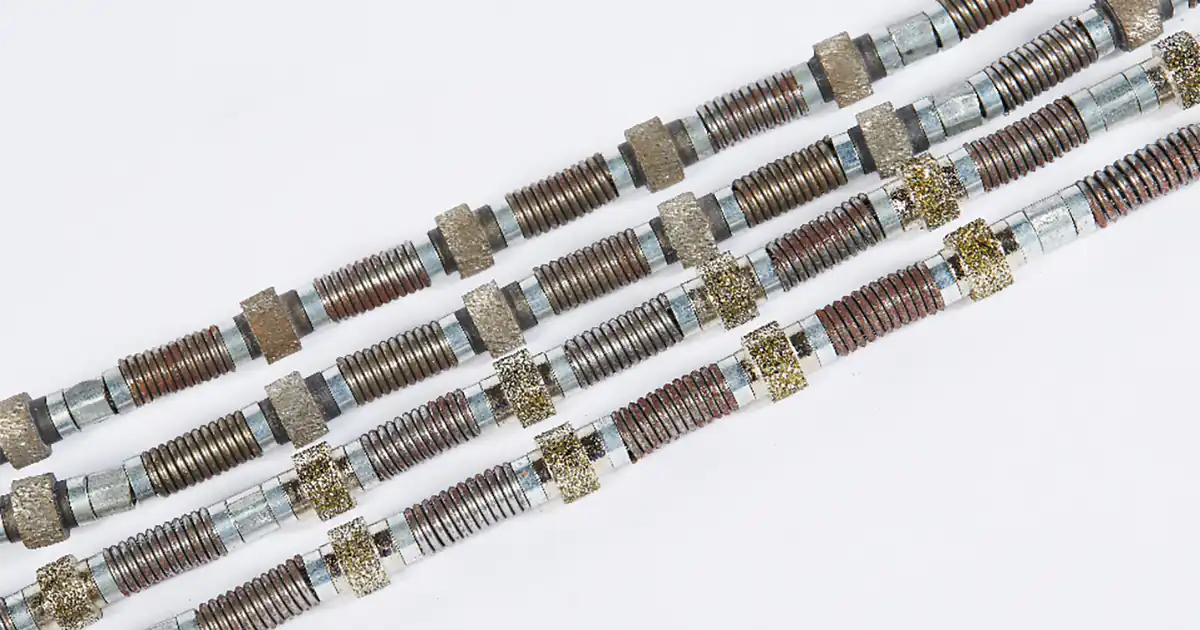

The diamond wire saws have been widely used in the mining of marble, limestone and sandstone mines, and has also been applied in the mining of granite mines because of its high sawing efficiency, good sawing quality, flexible use, strong applicability, low comprehensive mining cost, and high rate of mining waste materials.

Over the past 30 years, through continuous improvement and enhancement of diamond wire saws, the structure and technical performance of diamond wire saws are basically stable. There are many ways to classify diamond wire saws. Diawe Tools classifies diamond wire saws according to their maneuver, application, power mechanism and control system.

Classification According to Maneuver Mode

According to the different maneuver modes of diamond wire saws, they can be divided into: ① movable diamond wire saws are used for stone mining; ② Fixed diamond wire saw for shaping and profiled processing of block.

Mobile diamond wire saws are mainly used for stone mining operations, including some small mobile diamond wire saws specially used for blank shaping. The fixed diamond wire saw is specially used for blank shaping, plate cutting and processing, and processing of special-shaped stone products, which can be divided into portal and desktop structures.

Classification According to Application

According to different uses and types of stone materials, diamond wire saws can be divided into marble mining, granite mining, stone shaping and plate processing, special-shaped stone products processing and special-purpose diamond wire saws.

Mobile diamond wire saws are used to mine soft stones such as marble and travertine. The linear speed of the diamond wire saw is fixed, generally about 40m/s. For the mobile diamond wire saw used for mining granite hard stone, the linear speed of the diamond wire rope is adjustable, and the adjustment range is generally 20-40 m/s. The diamond wire saws used for block shaping have two structural forms: movable and fixed. The small movable diamond wire saws are mainly used for the mining of stone mines. The fixed diamond string saws used for blank shaping and plate processing can be installed in stone mines and used in plate processing plants. The diamond wire saws used for processing special-shaped stone products generally adopt numerical control systems and fixed structures. Small diamond wire saws used for cutting mosaic stones are all bench-type, and there are also fixed diamond wire saws used for processing tombstone stones. The special-purpose diamond wire saws used in the construction industry, which are specialized in the demolition and cutting of reinforced concrete and other building components or other purposes, generally adopt mobile structures.

Classification According to Power Mode

According to the different drive modes of diamond wire saw, it can be divided into a hydraulic diamond wire saw driven by hydraulic motor, an electric diamond wire saw driven by a motor, and an internal combustion diamond wire saw driven by diesel engine.

Whether fixed, mobile or bench type, the motor drive mode is the most widely used power mode of diamond wire saws at present. Most diamond wire saws in the world are driven by motors. Only a few variable speed and mobile diamond wire saws used for granite mining are driven by internal combustion engines. Electric diamond wire saws have become the standard structure of wire saws. Hydraulic diamond wire saw is the power mode adopted by the first-generation diamond wire saw, which has been eliminated and is no longer used.

Classification According to Control System

Due to the different control systems adopted by diamond wire saws, they can be divided into conventional electrical control, program control, PLC programmable variable frequency adjustable speed diamond wire saws and CNC wire saws. Mobile diamond wire saws are used for stone cutting, fixed diamond wire saws are used for shaping, and some of the fixed wire saws that process special-shaped stone products in a profiling manner and use conventional control systems are ordinary wire saws.