- Threading Diamond Wire Saw During Mining

- Threading Diamond Wire Saw Around the Vertical Cutting Surface of the Mining Separation Body

- Threading Diamond Wire Saw Around the Horizontal Cutting Surface of the Mining Separation Body

- Threading Diamond Wire Saw Penetration in the Initial Excavation Trench of the Closed Surface

- Threading Diamond Wire Saw Around the Disassembly or Shaping Surface

- Threading Diamond Wire Saw During the Processing of Special Shape Stone

- Threading Diamond Wire Saw for Fixed Rough Stone Block Shaping Machine

When using a diamond wire saw to cut large objects, sometimes it is necessary to first thread the diamond wire saw into the material. For example, during mining operations, a diamond wire saw must be wrapped around the cut surface before the cutting operation can be completed. Or when processing special-shaped stones, if it is necessary to cut the inner sealing surface of the stone or create a closed special shape, the diamond wire saw must also be threaded through and surrounded by the cut surface before cutting can be carried out.

Now, Diawe Tools will introduce the threading methods of diamond wire saws based on several common cutting scenarios.

Threading Diamond Wire Saw During Mining

During mining operations, the cut surface is divided into two types according to the different cutting purposes: ①the separated cutting surface; ②the disintegrated shaping cutting surface. According to the different cutting positions, the cut surface is further divided into ①vertical, ②horizontal, and inclined planes for cutting. There are slight differences in the method of diamond wire saw threading for different types of cutting surfaces.

Threading Diamond Wire Saw Around the Vertical Cutting Surface of the Mining Separation Body

The most basic threading operation method is to use a diamond wire saw to wrap around the vertical cutting surface of the mining separation body. It is usually divided into threading between the converging holes, threading between the drilling holes and the cutting surface, or threading across the holes between the drilling holes and the cutting surface or the burning surface.

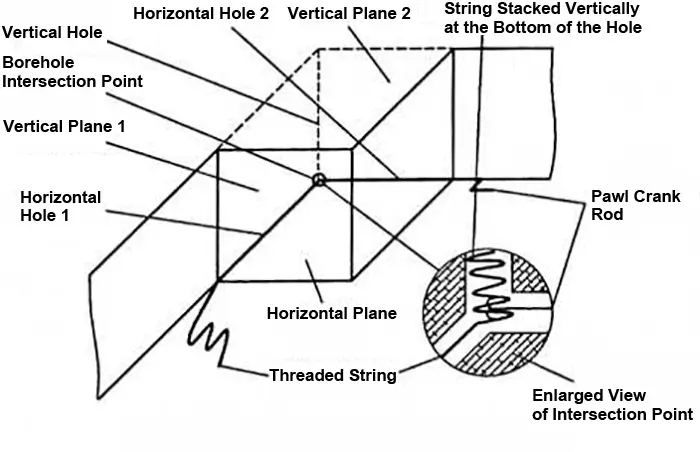

Ⅰ Method of Threading Diamond Wire Saw Through Holes on a Vertical or Horizontal Plane

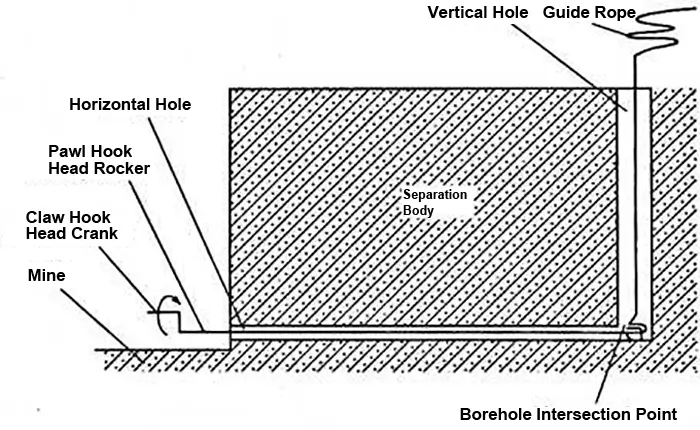

When the diamond wire saw needs to thread through the vertical or horizontal through-holes surrounding the vertical saw cutting surface, it can be penetrated according to the method shown in the schematic diagram below.

The basic step is to first pass the guide rope through the vertical hole and horizontal hole, and then connect the guide rope to the diamond wire saw. Under the traction of the guide rope, the diamond wire saw is threaded around the cutting surface.

Before threading, it is necessary to prepare a steel bar with a claw head and a handle. The diameter of the steel bar is 8-10mm, and the length exceeds the horizontal drilling hole by 50-100cm. The eccentricity distance of the handle is 15-20cm. The claw part is preferably made of high elastic steel wire, which is welded to the steel bar or wrapped with fine lead wire for fixation. The diameter of the head is 10mm smaller than the diameter of the horizontal hole. In addition, it is necessary to prepare cotton thread with a diameter of 1-1.5mm or flexible nylon thread as the guide rope, which should be at least 2-3m longer than the sum of the vertical and horizontal hole lengths, as well as several galvanized fine lead wires with a diameter of 0.8-1.5mm, plastic electrical tape, wire pliers and other auxiliary materials and tools.

The specific operation steps of threading a diamond wire saw are as follows: first, put the guide rope into the vertical hole, and the rope end forms a partial accumulation at the bottom of the vertical hole. The guide rope is firmly tied to the diamond wire saw an end, and the direction marked by the diamond wire saw must be consistent with the cutting movement direction. Thread the steel bar into the horizontal hole, so that the pawl head reaches the bottom of the horizontal hole, which is the intersection point of the drilling hole. Stir the shaking handle to pull out the rope accumulated between the pawl and the hole bottom from the horizontal hole, At this point, the diamond wire saw has passed through the vertical and horizontal holes on the cutting surface, forming a circle around the cutting surface. After preloading and connecting the diamond wire saw as needed, follow a reasonable installation method for the diamond wire saw and horizontal guide wheel, and complete the installation of the diamond wire saw before entering the cutting operation.

When the quality of drilling at the intersection point is poor and there is intersection deviation, which affects the passage of the guide rope and even the diamond wire saw, a thin galvanized lead wire can be added between the guide rope and the diamond wire saw to transition and improve the pulling strength of the diamond wire saw. When using fine lead wire and the diamond wire saw for connection, the part where the two are wound and connected must be wrapped with plastic electrical tape to improve the passability of the joint through the intersection hole and prevent the exposed lead wire joint from getting stuck at the intersection of the holes. If the use of fine lead wire still cannot help guide the diamond wire saw-through, a small number of explosives can be placed at the intersection of the drilling holes. After implementing a slight blasting, the intersection of the holes can be expanded, and after removing debris, the diamond wire saw can be easily guided through.

In addition, when the vertical and horizontal holes intersect accurately, other methods can also be used to guide the guide rope. For example, by connecting the guide rope to a lightweight ball and using water flushing or compressed air blowing, the ball is ejected from the vertical hole through the intersection point or blown out of the horizontal hole inlet, thereby taking out the guide rope. The lightweight ball can be made of a ping-pong ball, spherical polystyrene foam, and other materials, and its diameter must be about 10mm smaller than the minimum drilling diameter to ensure that the ball can pass through the hole smoothly.

Ⅱ Method of Threading Diamond Wire Saw Across the Hole Between Drilling and Cutting or Burning Surfaces

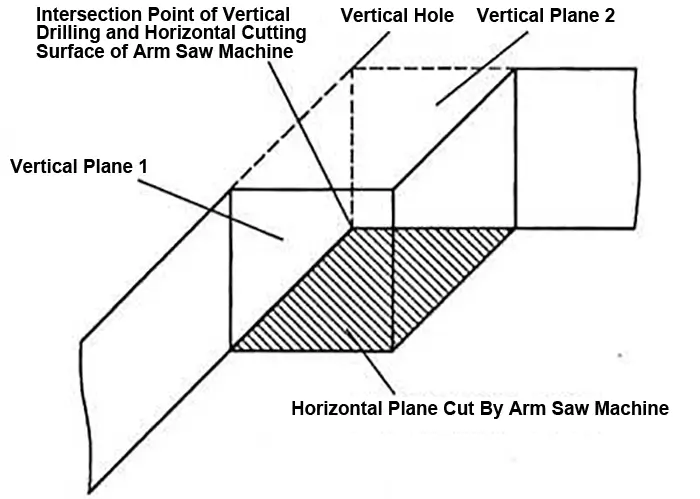

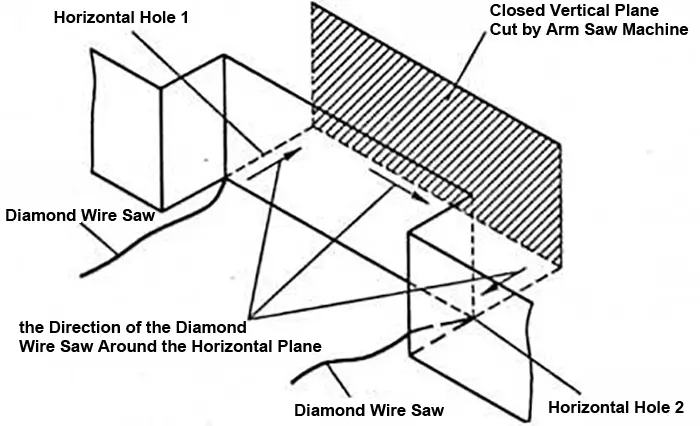

In marble mines where an arm saw machine is used to assist in mining and sawing, the horizontal surface or closed vertical back of the separation body has been pre-cut and separated from the ore body by the arm saw machine. The width of the cutting seam is 38-42mm, which is enough to pass through a diamond wire saw with a diameter of about 12mm.

When using a diamond wire saw to cut the vertical or horizontal plane connecting the separation body and the remaining connection of the ore body, as long as the vertical drilling hole is drilled through the horizontal plane cut by the arm saw machine using a drilling rig, and the diamond wire saw is inserted around the vertical plane, the two vertical sides of the separation body can be cut and separated, or the horizontal hole can be drilled through the vertical plane cut by the arm saw machine using a drilling rig, and the diamond wire saw is inserted around the vertical or horizontal plane, The separation and cutting of the remaining vertical and horizontal planes connected to the ore body can be carried out.

In granite mines where flame-cutting machines are used to dig trenches, a vertical plane of the separation body has usually been cut and separated from the ore body by flame-cutting machines, similar to the vertical plane of the separation body cut by an arm saw. As long as a rock drill is used to drill through the horizontal hole and the vertical cutting surface, the horizontal or vertical plane can be sawed after passing through the diamond wire saw.

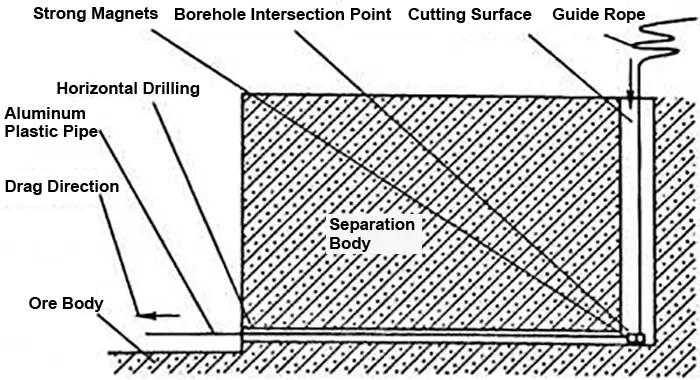

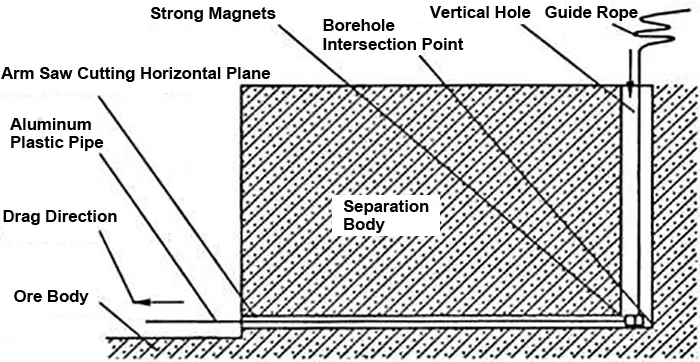

The following diagram is a schematic diagram of a diamond wire saw thread through a horizontal hole and a vertical cutting surface. This threading method requires the preparation of tools such as aluminum plastic pipes, strong permanent magnets, and thin nylon guide ropes. An aluminum plastic pipe with a strong permanent magnet fixed at the end, at least 0.5-1m longer than the horizontal drilling depth, with an outer diameter of about 15-20mm. The other permanent magnet is firmly bound to one end of the guide rope, and the maximum outer tangential diameter of the permanent magnet should be 10mm less than the horizontal drilling diameter. In this way, place the end of the guide rope with a permanent magnet into the cutting seam, so that the permanent magnet is near the intersection of the horizontal drilling and cutting surface. Then, insert one end of the permanent magnet of the aluminum plastic pipe from the horizontal hole until the two permanent magnets are attracted and combined. Then, extract the aluminum plastic pipe from the horizontal hole, and the guide rope is then taken out from the horizontal hole. The diamond wire saw connected to the other end of the guide rope can also penetrate through the horizontal hole, forming a circle around the vertical surface.

The following diagram is a schematic diagram of a diamond wire saw passing through a vertical hole and a horizontal cutting surface. The threading method and tool are the same as when a diamond wire saw passes through a vertical hole and a horizontal cutting surface. Just insert the guide rope with a magnet into the vertical drilling hole, and insert the aluminum plastic tube with the magnet tied into the horizontal saw slot. After cutting the first vertical plane, use the same method to thread the bead string and cut the other vertical plane.

If the depth of the vertical or horizontal cutting seam is relatively shallow, the threading method of the claw head reinforcement and the stacking guide rope introduced earlier can also be applied. However, when encountering deep-cutting seams, it is difficult to stack the guide rope at the intersection of the drilling and cutting seams. Using magnets to attract each other can achieve better and faster suction effects. For example, when passing through the vertical and horizontal holes, the magnet end in the horizontal hole should be penetrated into the vertical cutting seam first, and the guide rope should be shaken left and right to make the lower magnet swing relative to the intersection position of the hole and seam. Adjusting the depth of the magnet can easily make the two magnets touch and engage. On the contrary, in the case of vertical holes and horizontal sawing seams, a magnet with a guide rope is attached to the hole to fix it. Use the magnet end of an aluminum plastic tube to try to find another magnet at the intersection of the horizontal cutting seam and the vertical hole. Due to the attractive effect of a strong magnet, it is also very easy for the two to engage.

Threading Diamond Wire Saw Around the Horizontal Cutting Surface of the Mining Separation Body

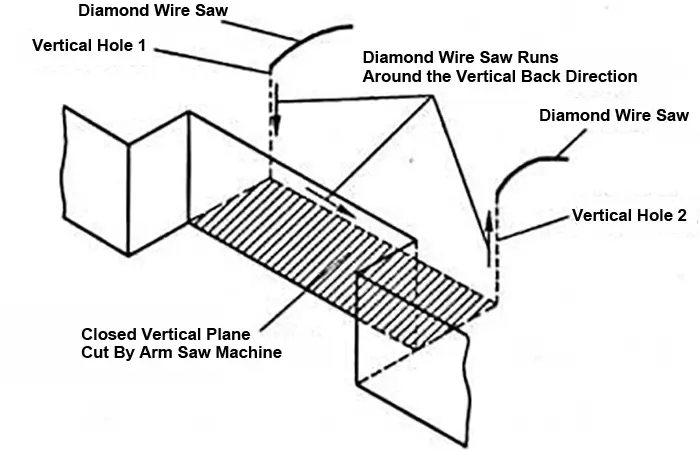

When cutting a horizontal plane with a diamond wire saw, it must be based on the implementation of two horizontal drilling holes and one vertical drilling hole intersecting and penetrating each other on the separated body. The following diagram shows the schematic diagram of the diamond wire saw threading around the horizontal plane.

The threading of the diamond wire saw around the horizontal sawing surface is based on the threading operation of the vertical sawing surface. When the cotton thread guide rope has been passed through a vertical hole and a horizontal drilling hole, forming a circle around a vertical sawing surface, all the cotton thread guide ropes at the vertical hole on the top of the separation body are placed into the intersection of the three holes to form a pile. The claw head reinforcement is inserted from another horizontal hole, and the other end of the cotton thread guide rope is pulled out from the second horizontal hole according to the method introduced earlier, forming a circle around the horizontal sawing surface of the cotton thread guide rope. Finally, connect the diamond wire saw with cotton thread or fine iron wire, and pull the guide rope while driving the diamond wire saw to complete the surrounding of the horizontal cutting surface.

When using the technology of burning the vertical surface or using an arm saw to cut the vertical surface for trench development, the method of threading a diamond wire saw around the horizontal cutting surface is relatively simple. When the diamond wire saw passes through the vertical cutting surface and horizontal drilling, forming a surrounding state for another vertical surface to be cut, the diamond wire saw inside the vertical cutting seam is pulled out from the cutting seam outlet and placed horizontally on the bottom surface of the cutting seam to form a cutting surround for the horizontal plane.

Threading Diamond Wire Saw Penetration in the Initial Excavation Trench of the Closed Surface

In the mining of soft stone materials such as marble, it is often encountered that a diamond wire saw threads through an arm saw machine to cut the vertical back or horizontal bottom surface of the separated body, forming a cutting groove around other surfaces.

When cutting a closed vertical back, the method of drilling horizontal holes through the vertical surface introduced earlier can be used. Two horizontal holes are drilled on both sides of the separation body to connect with the vertical back because the horizontal surface must be cut first. Therefore, the guide rope can be passed through one of the horizontal holes through the vertical back-cutting seam according to the method described earlier. Similarly, the other end of the guide rope can be passed through the second horizontal hole, Form a circle around the horizontal plane, and ultimately guide the diamond wire saw to circle the horizontal cutting surface, as shown in the following figure. After the horizontal bottom cutting is completed, the diamond wire saw can be used to wrap around the two vertical facades of the separation body according to the method introduced earlier, which can complete the cutting and separation of the other two vertical facades of the closed separation body.

If an arm saw machine is used to cut the closed horizontal bottom surface of the separation body, two vertical holes can be drilled and drilled separately at the appropriate position on the top surface of the separation body that needs to be back cut to connect with the horizontal bottom surface. Using the corresponding method introduced earlier, first thread the guide rope through the vertical facade surrounding one side, and then send the other end of the guide rope in the horizontal cutting plane to another vertical hole that intersects with the horizontal bottom. Using the same method as before, thread this end of the guide rope out of the inlet of the second vertical hole to form a loop around the closed vertical back. Tie the guide rope to the diamond wire saw, and finally pass the diamond wire saw through two vertical drilling holes and horizontally cut the bottom surface to form a cutting circle around the closed vertical back, as shown in the figure below. After the vertical back cutting is completed, follow the method introduced earlier to cut the two vertical facades of the separation body through the diamond wire saw, and finally complete the cutting and separation of the other two vertical facades of the closed separation body.

Threading Diamond Wire Saw Around the Disassembly or Shaping Surface

Usually, the separation body of a mine is divided into two situations: the disintegration of the overturned separation body, and the disintegration of the separated separation body directly on the ore body.

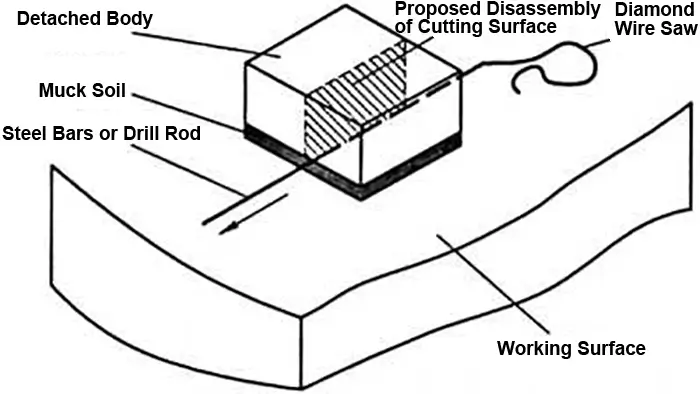

After the overturned separation body and the step surface of the ore body are padded with debris. After determining the separation cutting surface, steel bars or drill rods are used to pass through the debris at the required threading position between the separation body and the step surface. The guide rope or diamond wire saw is directly tied to one end of the steel bar or drill rod. After pulling out the steel bar or drill rod, the diamond wire saw then passes through the gap between the separation body and the step surface, and can be disassembled and cut after surrounding the separation body, as shown in the following figure.

When encountering a large volume, difficulty in overturning, or a small mining face size that cannot accommodate the overturned separation body, the large separation body can be first decomposed into small separation bodies on the ore body, and then overturned. When the volume of the separation body is large and cannot be moved, first drill a vertical and horizontal intersection hole at the disassembly surface position, and follow the method introduced earlier to thread a diamond wire saw to surround the disassembly surface and carry out cutting. If the separation body is lifted away from the ore body, resulting in a gap with a width greater than 40mm between the separation body and the ore body, a horizontal hole can be drilled to connect with the gap according to the position of the disassembly cutting surface. The diamond wire saw can be inserted around the cutting surface according to the method introduced earlier for inserting the diamond wire saw on the opposite side of the hole between the horizontal hole and the vertical cutting seam.

When shaping rough stone blocks, this method can also be used for the operation of threading diamond wire saws.

Threading Diamond Wire Saw During the Processing of Special Shape Stone

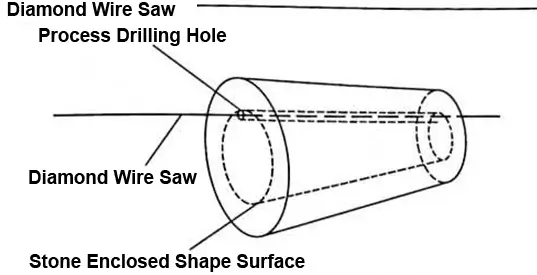

When using a multi-dimensional CNC diamond wire saw machine to process special-shaped stone products, the stone block can be directly placed around the diamond wire saw for cutting. When processing the inner closed molding surface of three-dimensional special shape stone products, a process drilling hole must be drilled on the stone block first, and the diamond wire saw must be threaded and connected through the hole before cutting can be carried out. After completing the cutting, it is necessary to cut the diamond wire saw in order to remove the special shape stone products.

Threading Diamond Wire Saw for Fixed Rough Stone Block Shaping Machine

When using a fixed rough stone block shaping machine to shape and cut rough stone blocks, there is no need to thread the diamond wire saw. The diamond wire saw is usually divided into two structures: without connectors/joints and with connectors/joints. As long as the diamond wire saw is installed on the shaping machine, the shaping machine is in a ready processing state. When shaping, simply place the rough stone block on the ground of the rough stone block shaping machine trolley or its cutting position to shape and cut the stone.