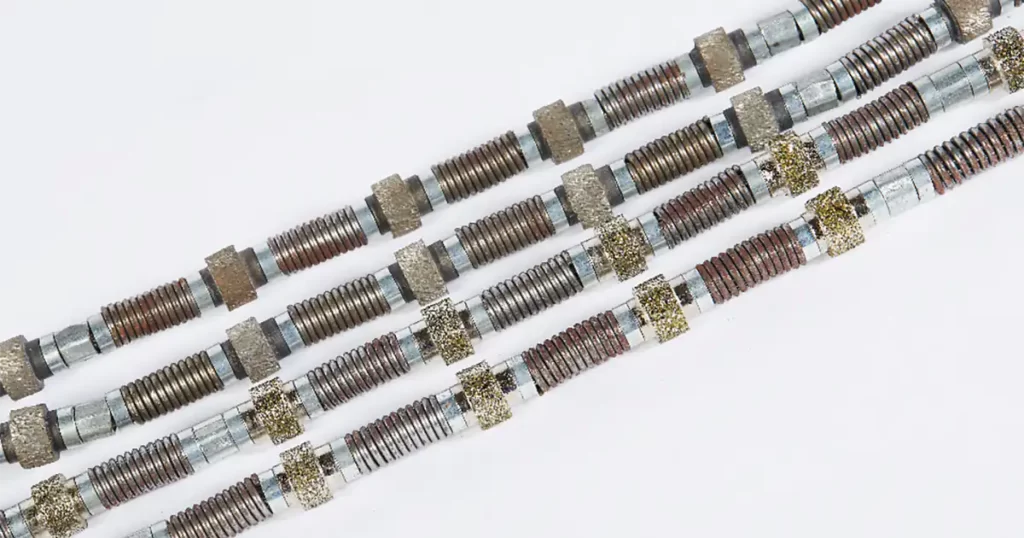

The wire rope for the diamond wire saw is usually braided from 3.5-4.9mm diameter, 61-133 strands of wire rope for stringing diamond beads, crimps, connectors, fixing structures in different materials such as spring/plastic/rubber together, bears the tension of the saw machine and acts as a connection when cutting stone or concrete.

Depending on the diameter, construction, application and technical performance parameters of the wire rope, Diawe Tools presents several of the most common types of wire rope.

Types and Uses of Wire Rope

Common wire ropes are divided into conventional type, high-strength type, no-clean type, special no-clean type, plastic core type, galvanized and copper-plated type, etc.

Conventional Wire Rope

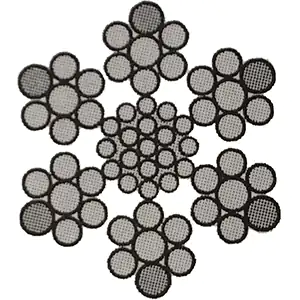

The outer diameter of conventional steel wire rope is 3.8mm and 4.9mm. It is made of 61 strands of 0.4mm and 0.52mm galvanized steel wire rope. The diamond wire saw produced by conventional wire rope is mainly used for mining marble and granite.

High-strength Wire Rope

The outer diameter of high-strength wire rope is 4.9mm, which is woven by 61 strands of galvanized steel wire rope. Different from the conventional wire rope, the outer surface of the high-strength wire rope adopts a special plastic coating similar to the protective layer, which firmly wraps the surface of the high-strength wire rope to maintain its structural compactness, prevent the abrasion caused by impurities in the cutting process, and the oxidation inside the wire rope under the action of cooling water, so as to maintain the long service life of the high-strength wire rope. It is mainly used to produce spring-type diamond wire saw for mining marble. This kind of wire rope coated with plastic protective layer is not suitable for plastic injection diamond wire saw.

No-clean Wire Rope

The specification of 61 strands of no-clean/clean-free wire rope is the same as that of conventional wire rope. In order to be more suitable for the production process requirements of plastic injection diamond wire saw, each steel wire rope is specially cleaned during the production, which removes the pollution of grease and other sundries on the steel wire rope during the production process, and improves the adhesion of polyurethane plastic and steel wire rope during the production of plastic injection diamond wire saw. In the core rope mechanism of the special no-clean wire rope specially designed and developed for the plastic injection production process to increase the injection adhesion, one of the seven steel wire ropes per share has a relatively large diameter, which is used to increase the external contact area of the wire rope and improve the combination characteristics of the wire rope and the plastic material during injection molding. 61 strands no-clean wire rope is mainly used to produce diamond wire saw for marble and granite cutting and shaping.

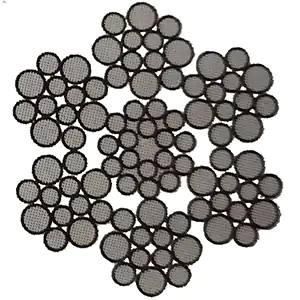

The outer diameter of 90 strands no-clean wire rope is between 3.5-4.9mm, with five specifications. In addition to maintaining the same advantages of 60 strands no-clean wire rope, it also has better flexibility, abrasion resistance and impact resistance. It is not only used for the core rope of diamond wire saw for marble and granite mining and cutting, but also for the core rope of diamond multi-wire saw.

Plastic Core Wire Rope

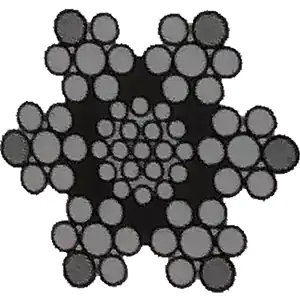

The plastic core wire rope has two specifications: 61 strands and 90 strands. During manufacturing, a plastic layer is wrapped around the metal core rope, which is used to expand the use temperature range of the plastic core wire rope. When the bead rope is used continuously in the range of – 2~+80 ℃, the diameter of the wire rope remains basically unchanged, and the wire rope is not prone to brittle fracture. The plastic layer can also maintain the stability of the wire rope when the wire rope is subjected to lateral force, torque force caused by lateral deviation and impact load. The plastic core wire rope is mainly used to produce plastic injection diamond wire saw for cutting marble and granite, including diamond multi-wire saw and diamond single wire saw.

Galvanized and Copper Plated Wire Rope

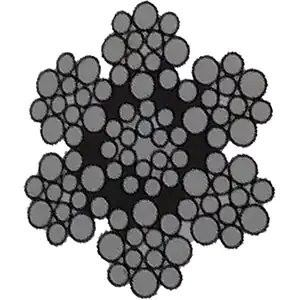

Galvanized and copper-plated wire rope usually adopts 133 strand steel wire rope structure, with outer diameters of 4.8mm or 4.9mm. Each thin steel wire rope adopts galvanized or copper-plated process, which is more suitable for producing the core rope of plastic or rubber injection diamond wire saw. Because more strands of the galvanized and copper-plated wire rope are used, the breaking force of this wire rope is higher than that of 61 or 90 strands of wire rope.

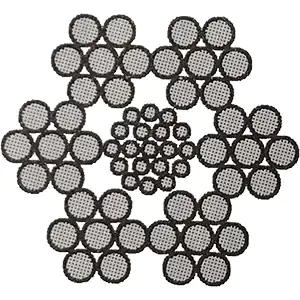

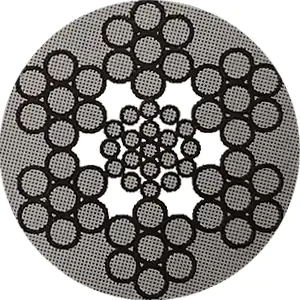

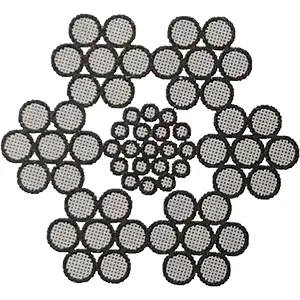

Structure and Technical Parameters of Wire Rope

Based on our research & development and market experience, Diawe Tools summarized common wire rope structures and technical parameters, as shown in the following table.

| Structure Diagram | Types of Wire Rope | Number of Steel Wire Strands | Outer Diameter/mm | Diameter of Steel Wire/mm | Minimum Breaking Force/N |

|---|---|---|---|---|---|

|

Galvanized Conventional Wire Rope | 61 | 3.8 | 0.4 | 11000 |

| 4.9 | 0.52 | 18350 | |||

| Be used to produce rubber diamond wire saw for marble and granite mining. | |||||

|

Galvanized High-strength Wire Rope (Diameter deviation 0+0.15mm) |

61 | 4.9 | 0.52 | 18350 |

| Be used to produce spring type diamond wire saw for marble and granite mining. | |||||

|

Galvanized No-clean Wire Rope | 61 | 3.8 | 0.4 | 11000 |

| 4.9 | 0.52 | 18350 | |||

| Be used to produce diamond wire saw for marble and granite mining, cutting and shaping. | |||||

|

Galvanized Special No-cleaning Wire Rope | 61 | 3.8 | 0.4 | 11000 |

| 4.9 | 0.52 | 18350 | |||

| Be used to produce plastic injection diamond wire saw for marble and granite mining cutting and shaping. | |||||

|

Forged Zinc No-cleaning Wire Rope | 90 | 3.5 | 0.33 | 9890 |

| 3.8 | 0.36 | 11000 | |||

| 3.9 | 0.37 | 11600 | |||

| 4.5 | 0.42 | 15390 | |||

| 4.9 | 0.46 | 18350 | |||

| Be used to produce diamond wire saws for marble and granite mining cutting and shaping cutting, and can also be used to produce diamond multi-wire saws. | |||||

|

Plastic Core Wire Rope Type-1 | 61 | 3.8 | 0.4 | 11000 |

| 4.9 | 0.52 | 18350 | |||

| Be used to produce plastic injection diamond single wire saw or multi-wire saw for the cutting of marble and granite. | |||||

|

Plastic Core Wire Rope Type-2 | 90 | 4.9 | 0.52 | 18350 |

| Be used to produce plastic injection diamond single wire saw or multi-wire saw for the cutting of marble and granite. | |||||

|

Galvanized Wire Rope | 133 | 4.8 | 0.38 | 22000 |

| Be used to produce the plastic injection diamond single wire saw for marble and granite mining cutting and shaping cutting. | |||||

|

Copper-plated Wire Rope | 133 | 4.9 | 0.32 | 22000 |

| Be used to produce plastic or rubber injection diamond wire saw for marble and granite mining & shaping cutting and concrete cutting. | |||||

Conclusion

The design and use of the wire rope of the diamond wire saw are determined by the cutting environment and cutting object of the diamond wire saw. Therefore, it is necessary to first know what types, structures and performance characteristics it has, and then comprehensively consider the use.

Of course, for the users of stone processing or concrete cutting, it is not necessary to know so many details, and excellent diamond wire saw manufacturers have fully considered it. However, if there are faults in the use of diamond wire saw, such as broken rope, rusted rope core, etc., these can be used for troubleshooting.