Diamond wire saw has become the main tool in the field of stone mining and processing, which includes the processing of stone blocks. Diawe Tools will introduce the processing of stone blocks by diamond wire saws under two scenarios of mines and stone processing plants.

Why Process Stone Block

It is necessary to reshape stone blocks, especially in mines. Its advantages are that the size of the block after shaping treatment is regular, the squareness is good, and the gross volume is very close to the real volume of the block after acceptance. Because the transportation cost of stone blocks is calculated according to their weight, the closer the gross volume is to the solid volume, the less stone blocks will be. Therefore, the transportation cost of useless parts on the stone blocks will be reduced.

Taking the full sawing method for stone mining as an example, if the six sides of the block have been reshaped, the gross volume density will only increase by about 16%~18% compared with the solid volume density of the block. If the bulk density of the block is 2.8 t/m3, the gross volume density will be about 3.3 t/m3, that is, the weight of the useless part of each cubic meter of the block will increase by about 0.4-0.5 too if the dense hole arrangement is used to reshape the block. According to the actual measurement and weighing statistics, the granite block with good splitting properties, smooth six shaping surfaces, good squareness and a volume density of 3 t/m3 has a gross volume density of 4 t/m3, which means that the gross volume density increases by about 33% compared with the real volume, and the useless part of the block per unit volume reaches 1 t. If the six sides of the block are simply trimmed and its squareness is relatively poor, the gross volume density of granite block with a volume density of 3 t/m3 will reach 4.5 t/m3, some as high as 5 t/m3, and the worst even exceeds one time of the solid volume density. Therefore, the transportation cost of unrefined or poorly trimmed blocks will be doubled at most.

Many stone mines in China are located in the inland and western regions, 1000-2000 km away from coastal ports or stone-developed areas, some even 3500 km away. The freight of the block has been 3-4 times higher than the mining cost, and some even up to 6-8 times. If the block is not reshaped, the freight generated by the useless part of the block will account for a considerable part of the total cost of the block, saving this part of the cost and improving the economic efficiency of the stone, It is of practical significance to reduce the price of raw materials and improve the market competitiveness of products. Therefore, it is suggested that the shaping treatment should be completed at the stage of stone mining.

Another advantage of the shaping block is reflected in the plate processing, especially in the large plate processing. The flat top surface of the block can save the sawing time of the sand saw or row saw.

Diamond Wire Saw for Shaping Stone Block in Mine

Normally, the shaping of stone blocks is usually completed in mines. In marble mines, mobile wire saws or special fixed wire shaping machines can be used. In granite mines that adopt the full sawing mining technology of diamond wire saws, most of the granite blocks have been reshaped by mobile wire saws during the mining process. In mines that use wire saws to assist in granite mining, mobile wire saws can be used to reshape and treat the stone block as required. In granite mines that are mined by other methods without the aid of diamond wire saws, fixed wire saw shaping machines can also be installed to reshape the quarried granite blocks.

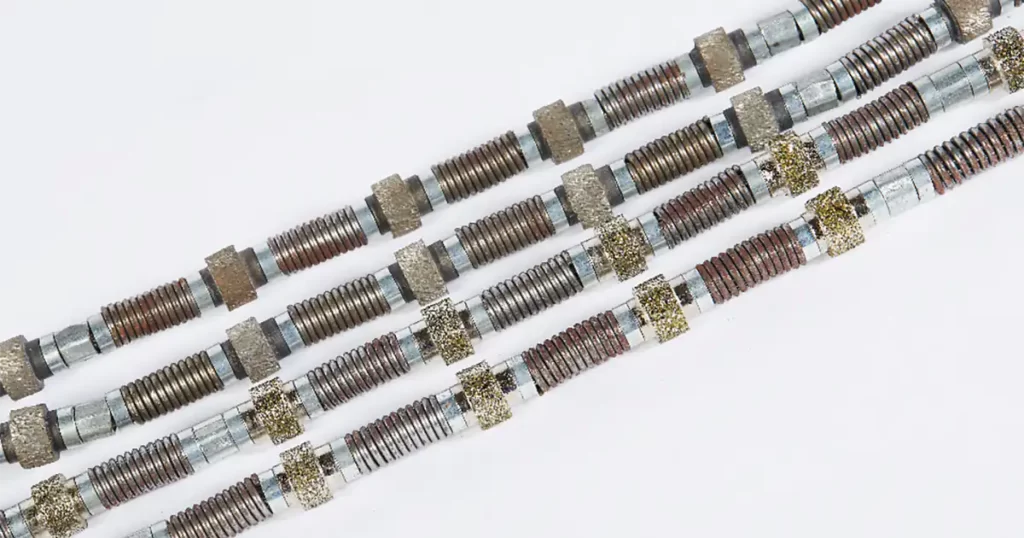

The special blank shaping equipment used in stone mines includes small mobile diamond wire saws and fixed diamond wire shaping machines. When necessary, large and medium-sized diamond wire saws used for large face cutting on mining benches can also be used for blank shaping.

At present, most stone mines mainly use mobile diamond wire saws to shape stone blocks at the mining site.

Diamond Wire Saw for Shaping Stone Blocks in Stone Processing Plant

The installation of the shaping machine in the plate processing plant is actually the second and last shaping process for stone blocks. At present, many stone processing plants at home and abroad are equipped with fixed block shaping equipment, and the fixed diamond wire saw shaping machine is the most used block shaping equipment in stone processing plants.

Because the marble is relatively soft, in addition to the fixed wire saw shaping machine, such as the single saw blade shaping machine, the diamond band saw shaping machine, and even the fixed chain arm shaping machine can finish the finishing of marble blocks. However, the fixed wire saw shaping machine has been accepted by many marble slab manufacturers because of its very high shaping and cutting efficiency and appropriate shaping cost, and has basically become the preferred model of fixed shaping equipment for marble slab manufacturers.

In the granite slab production plant using sand saws, because the granite is hard, the diamond wire saw shaping machine and other ordinary shaping equipment used by the marble slab processing plant can not complete the shaping and cutting of the granite block, so the fixed diamond wire saw shaping machine has become the only blank shaping machine equipped by the granite slab production enterprise.

The fixed wire shaping machine used in the stone plate processing plant can also be installed in the stone mine, which is used in the stone mining site to shape and cut the block.

Advantages of Using Fixed Diamond Wire Saw Machine in Stone Processing Plant

When using sand saws to process granite and row saws to process marble slabs, the flatness of the top surface of the stone block is highly required. The flatness of the top surface of the block directly affects the production efficiency of the sawing machine.

Taking the processing of granite slab as an example, the height of the sand saw blade is generally 100 mm, and the stone cut by the saw blade is divided into the “cut in” stage and the normal feeding stage. When the saw blade starts to contact the stone and the depth of the cutting stone reaches 80% of the height of the saw blade (the depth varies slightly depending on the hardness and cutting performance of the stone), it is called the “cutting” stage of the saw blade. The two sides of the saw blade in the “cut in” stage are basically free and unsupported. The cutting rigidity of the saw blade is very poor, and it cannot reach the normal cutting feed speed. The feed speed of the falling saw is usually only 15% – 25% of the normal feed speed, and generally only about 0.8-1 cm/h. For cutting some hard stones, the feed speed in this stage may be low. In this way, it can ensure that the saw blade cuts into the blank vertically without deflection and that the saw seam is straight. The normal cutting stage can only be started when the depth of the saw blade cutting into the stone exceeds two-thirds of its height. The normal cutting feed speed is generally 2~5 cm/h.

If the top surface of the granite block is shaped and leveled by a fixed diamond wire saw, the flatness error can reach ± 0.5 cm, which can generally be guaranteed to be ± 1 cm, that is, the total deviation is within 2 cm. According to the processing parameters listed in Table 3-1, the “cut in” stage of the saw blade takes about 8~10 hours. If the top surface of the granite block is only manually leveled, the best flatness error can only reach 10 cm at most. The time required for the saw blade to complete the “cut in” phase is about 14~18 hours, which is almost twice as long as processing the top block after diamond wire sawing. If the height of the block is 1.8m, the depth of the cut block in the sawblade “cut in” stage of processing the top trimmed block only accounts for about 5.5% of the whole height of the block, but the time consumed accounts for about 10% – 16% of the whole cutting time; If the top surface of the processed block is not trimmed, the “cut in” depth of the saw blade accounts for about 10% of the total height of the block, and the time consumed accounts for about 17%~25% of the total cutting time. From the above analysis and calculation, it can be seen that 8~10h of the time spent in cutting granite blocks with an unevenness error of 10 cm on the top surface is spent cutting the uneven part of the top surface of the block. During this period, the cutting effect of the sand saw is basically useless, but it is a waste of power and labor costs. In order to improve the production efficiency of the sand saw and reduce the cutting cost, it is necessary to trim the top surface of the block.