Concrete materials are closely related to our daily life and are widely used in municipal, housing, road and other engineering projects. During the rectification and processing of old buildings, special tools are sometimes used for cutting, such as opening a door on the wall and cutting off redundant reinforced concrete blocks on the bridge. In the case of construction where the requirements for cutting accuracy are not very strict, diamond wire saws can be used to cut concrete.

Why Use Diamond Wire Saw to Cut Concrete

At present, some of the main construction equipment used in the field of building material cutting have defects such as large overall dimensions, great environmental pollution and non environmental protection. Especially in the narrow construction site, it is particularly difficult to operate. The main reason for these shortcomings is that according to the construction machinery design specifications, there is a need for a better safety factor, heavy machinery design and high-power power components, so there is a contradiction between design machinery and construction requirements. The diamond wire saw cutting system for small building construction has made up for the shortage of large construction machinery, and has gradually become an indispensable construction machinery in building construction, especially in special locations.

Concrete diamond wire saw has incomparable advantages in the nondestructive demolition of buildings, and is widely used in the world. When removing reinforced concrete components, the diamond wire saw has the characteristics of simple operation during cutting operation, convenient movement and installation of ultra light saw machines, high cutting efficiency, no dust and noise pollution, small overall vibration and no damage to buildings. It can cut and remove reinforced concrete, stone, masonry and other building structures, and is also suitable for cutting steel pipes, piers, bridge structures and other components.

Compared with other demolition methods, the concrete diamond wire saw can be operated safely, efficiently and accurately in limited space, and is especially suitable for the interior of buildings and different levels of multi-storey buildings. In addition, the system can also be used for building repair and cutting operations in repair. For example, the cutting operation of inserting damp proof course into decayed structures, and the cutting operation of adding noise proof isolation layer between buildings. Due to the high cutting accuracy of diamond wire saw, in the construction of some bridges built with concrete components, diamond wire saw can be used to cut the matching parts of prefabricated components in advance, so as to improve the installation and matching accuracy of components.

Main Structure of Concrete Diamond Wire Saw

Concrete diamond wire saw mainly includes main power system, feeding system, bead wire storage device, saw frame, guide wheel and diamond wire.

Main Power System

The main power system is used to drive the main flywheel to rotate and drive the diamond wire saw to complete the cutting operation. At present, the concrete diamond wire saw can use a motor and a hydraulic motor as the drive power of the diamond wire. According to the use characteristics of the concrete diamond wire saw, the motor driven sheave is more suitable for its use requirements, and can reduce the cumbersome hydraulic system and improve the mobility of the concrete diamond wire saw.

The diameter of the main flywheel is generally between 300 mm and 800 mm. During design, corresponding guide wheels must be equipped to control the envelope angle between the diamond wire saw and the main flywheel to prevent slipping between them and affect power transmission.

Feeding System

Among the concrete diamond wire saws, the most commonly used method is to drive the flywheel to move along the guide rail to achieve the cutting feed motion of the diamond wire saw, which is different from the diamond wire saw feed cutting method used for stone cutting. Usually, the hydraulic cylinder is used to drive the drive wheel of the diamond wire to achieve the feeding. If the saw system is installed on a trolley with a mobile wheel, when the drive wheel moves to the end of the guide rail, the trolley can be moved to move the drive wheel to the front of the guide rail, and the cutting and feeding movement within its travel can be completed again. The obvious disadvantage of the hydraulic feeding system is that it requires an independent hydraulic power unit and many hydraulic oil pipes to connect. It is inconvenient to move and operate the saw, and the maintenance of the hydraulic system is complex. Therefore, many concrete diamond wire saws now use motor feed drive system, which is simple in structure and more suitable for operation under harsh working conditions.

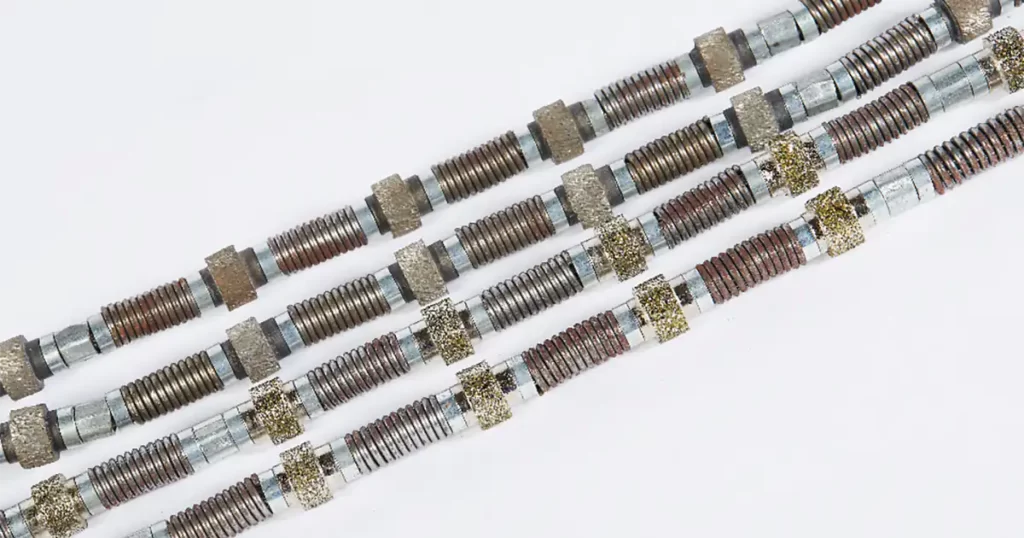

Diamond Wire

Different kinds of concrete have different structural components. For reinforced concrete structures with reinforced skeleton, they can be divided into various specifications of reinforced concrete according to their use, diameter of reinforcement and density of reinforcement mesh. Plain concrete structures, stone and masonry structures without reinforcement processing framework belong to another type of concrete. When cutting different kinds of concrete, the saws used are the same, but the diamond wire selected is different from the diamond wire used for mining and processing stone materials.

Theoretically, reducing the diameter of diamond wire can reduce the sawing force and power consumption of the sawing machine. However, there will be another problem. For diamond wires with smaller diameters, their wear resistance will be reduced, their service life will be reduced, and the frequency of diamond wire replacement will increase, especially when cutting in a large area, which will increase the complexity of the operation.

Diawe Tools uses a diamond wire with a diameter of 8.5mm to conduct a cutting test of 11m2. The cutting section is a reinforced concrete structure, of which 2% is steel. In the cutting test, it was found that the cutting pressure decreased significantly. When the diameter of diamond wire decreased by 25%, the feed pressure of diamond wire also decreased by about 25%. Compared with the ordinary diameter diamond wire, the deviation of cutting surface can be controlled in a very small range during machining.

Another test shows that the tensioning force and energy consumption of small diameter diamond wire are about 40% less than those of 11.5mm diameter diamond wire. Although the feed tension is reduced by 1.0MPa compared with the original operation, the cutting time will not increase because the feed tension is still at a relatively high level and the cutting area under the action of thinner diamond wire is reduced. On the contrary, compared with the diamond wire with a diameter of 11.5mm, the time for cutting 1m2 is reduced by 30%. Therefore, the smaller the diameter of the diamond wire, the less energy it needs to consume when working, and the smaller the cutting tension. These test results are consistent with the results obtained from the study of granite mining with diamond wire.

In addition, the noise level produced by diamond wire saws with different diameters is also different according to the test. The level of diamond wire sawing noise is also related to the cutting speed, but the influence factor of the latter is very small. The main influence factor is the diamond wire diameter. For a diamond wire with a diameter of 11mm, when the cutting line speed is 16.7m/s, the noise generated by the diamond wire is generally 92dB. For a diamond wire with a medium diameter, the noise generated at a normal cutting speed is about 89dB; If the thinner string is used for cutting, the noise generated is only about 87dB. This data shows that the use of thin diamond wire can reduce noise by about 5dB.

Usage of Concrete Diamond Wire Saw

The cutting principle of concrete diamond wire saw is basically the same as that of stone diamond wire saw. Because the operation site of concrete diamond wire saw is usually narrow, its use method is slightly different from that of stone mining/quarrying.

Concrete diamond wire saw must be equipped with more auxiliary devices when it is used. In order to meet the requirements of the complex space inside the building, the guide wheel must be equipped. In order not to damage the building parts that do not need to be removed, the guide wheel bracket and guide wheel shall be installed on the removed or cut components as much as possible. When cutting and removing the vertical components, the guide wheel and its bracket shall be installed and fixed on the vertical components, so corresponding vertical anchors must be equipped. Or the guide wheel and its bracket shall be equipped with a device anchored on the vertical wall.

If it is to demolish outdoor building components, such as bridges, rock drills or positioning drills can be used to drill the required intersection holes. If the cutting operation is carried out in the buildings, in order to reduce or prevent vibration and noise, the electric drill can be used to drill the intersection holes. The basic use methods of two concrete diamond wire saws are introduced below.

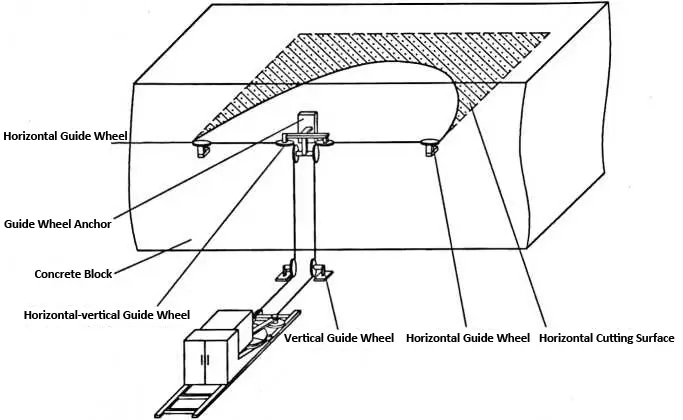

Horizontal Cutting of Concrete Diamond Wire Saw

When cutting the horizontal plane of the building, if the difference between the cutting plane and the installation plane of the concrete diamond wire saw is small, the same method can be used as horizontal cutting in mining. However, when cutting and removing components such as ceilings, because the cutting plane is much higher than the installation plane of the concrete diamond wire saw, a group of guide wheels should be used to guide the concrete wire saw from the installation plane of the saw to the cutting plane.

When cutting buildings with different horizontal surfaces, first install a pair of vertical guide wheels at the front end of the concrete diamond wire saw, install a set of reversing guide wheel components including a pair of vertical and horizontal guide wheels at the position of the horizontal surface to be cut, and install a horizontal guide wheel near the drilling entrance of the cutting surface with the same level as the horizontal guide wheel in the guide wheel component. The concrete diamond wire from the main flywheel of the diamond wire is guided to the cutting surface through the guide wheel, forming a cutting circle around the cutting surface. The vertical guide wheel shall be anchored on the installation ground plane of the diamond wire saw, and the horizontal guide wheel and the guide wheel shall be anchored on the vertical wall to be cut.

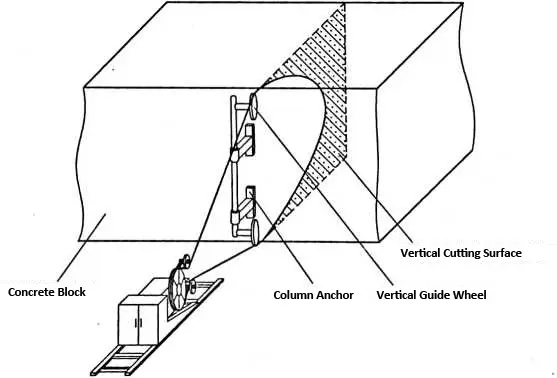

Vertical Cutting of Concrete Diamond Wire Saw

When cutting vertical concrete blocks, the vertical cutting column with the guide wheel is fixed on the vertical wall by two anchors. The threading of diamond wire, and the installation of diamond wire and guide wheel are the same as the cutting method used in mining and cutting the vertical plane.

When removing and cutting concrete components, appropriate equipment installation and cutting methods shall be selected according to the actual working terrain, size of working space and actual conditions of power supply. In order to adapt to complex working terrain conditions, the guide wheel should be used as far as possible to guide the diamond wire to the cutting plane, so as to minimize the damage to buildings.