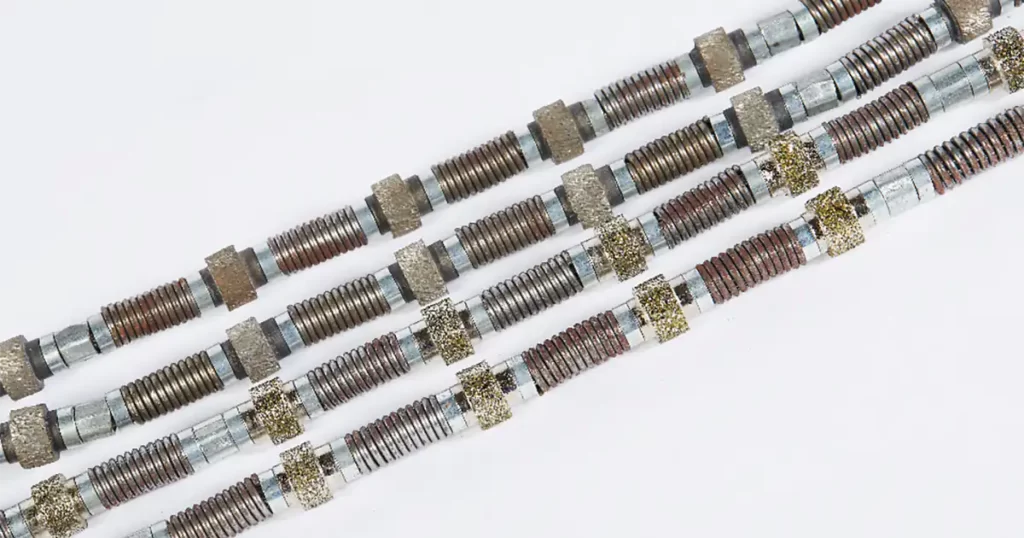

The diamond wire saw bead(also called diamond bead, diamond wire bead) is a part of the diamond wire saw. It usually presents a cylinder with a hollow center and is mainly composed of alloy powder and diamond. A number of diamond wire saw beads are strung on the steel rope, separated by the steel ring and spacer sleeve, forming a basic diamond wire saw, which is the component responsible for grinding and cutting when cutting stones, concrete and other materials.

According to different cutting objects and applications, there are different specifications of diamond wire saw beads, mainly including the diameter, quantity per meter, manufacturing process and formula of diamond wire saw beads. The formula of diamond wire saw beads usually means the proportion of various materials in the diamond wire saw beads. The formula is determined by continuous testing according to the grading of stone hardness and wear. At present, the commonly used diamond wire saw beads manufacturing processes include electroplating and hot-pressing sintering, as well as two rarely used methods of impregnation and brazing.

Specifications of Diamond Wire Saw Beads

Diawe Tools has listed the common diamond wire saw specifications in the market before. Here we list the common diamond wire saw bead specifications in the market, see the table below.

| Size of Diamond Wire Saw Beads(mm) | Dimension of Diamond Bead Framework | Manufacturing Process | ||||

|---|---|---|---|---|---|---|

| Diameter(mm) | Length(mm) | External Diameter(mm) | Length(mm) | Internal Diameter(mm) | Inner Hole Processing Status | |

| 6 | 6 | 4 | 8.6 | 3 | Threaded Hole | Electroplate |

| 8.7A | 6 | 6 | 9 | 4 | Threaded Hole | Sinter |

| 8.7B | 6 | 6.5 | 9 | 5 | Threaded Hole | Sinter |

| 9.3 | 5.5 | 8 | 9 | 5 | Smooth Hole | Sinter |

| 10 | 5.5 | 8 | 8.5 | 5 | Smooth Hole | Electroplate |

| 10.5 | 6.5 | 8 | 10 | 5 | Smooth Hole | Sinter |

| 11 | 7 | 8 | 10 | 5.2 | Threaded Hole | Sinter |

| 11.2A | 6.5 | 8 | 10 | 5.2 | Smooth Hole | Sinter |

| 11.2B | 6.5 | 8 | 10 | 5.2 | Threaded Hole | Sinter |

| 11.2 | 6.5 | 8 | 10 | 5 | Smooth Hole | Electroplate |

| 13.2 | 7 | 8 | 10 | 5 | Smooth Hole | Sinter |

If we want to know what diamond wire saw bead is, we should not only know the specifications, but also the manufacturing processes.

Electroplated Diamond Wire Saw Bead

Electroplated diamond wire saw beads are composed of bead framework made of steel ring, diamond particles and bonding metal. The diamond particles are electrodeposited on the outer surface of the bead framework by the electroplating process. With the growth of the electroplating layer, the diamond particles are embedded in the layer.

Electroplated diamond wire saw beads are characterized by simple manufacturing process, low production cost, good self-sharpening performance when cutting soft stone,such as marble, and high sharpness throughout the effective cutting life. The disadvantage of the electroplating process is that the deposited electroplating metal layer is very thin, and the diamond particles can only be distributed in this very thin electroplating metal layer. As the electroplating layer is abraded, the diamond particles will wear and fall off quickly, and its cutting performance will gradually lose, so the service life of the electroplated diamond wire saw beads is relatively low.

Impregnated Diamond Wire Saw Bead

Impregnated diamond wire saw beads are composed of a steel bead framework ring and a diamond impregnation ring surrounding the outer circumference of the framework ring. The impregnation ring is made of aluminum carbide powder and diamond particles. During manufacturing, copper, nickel, cobalt, Yi and other metal powders that act as bonding agents are placed around the impregnating ring. When heated at a high temperature of 1200-1300 ℃, the bonding metal powder is melted and immersed into the impregnating ring, closely fused with the skeleton metal and diamond, and combined into a solid cutting carrier, that is the impregnated diamond wire saw bead.

Unlike the electroplated diamond wire saw bead, which has only a very thin layer containing diamond particles, diamond particles are uniformly distributed in the impregnated ring with a certain thickness. After each layer of base metal is abraded, new diamond particles will be exposed, maintaining the sharpness of the diamond wire saw bead, so that the diamond wire saw bead has consistent cutting performance throughout the cutting life and has a long life. Another feature of impregnated diamond wire saw beads is that the cutting performance of diamond beads can be adjusted by adjusting the proportion of different metal powders in the matrix, so as to adapt to the cutting of stones with various hardness.

The disadvantage of impregnated diamond wire saw beads is that the metal of the matrix is relatively hard, and it is only suitable for cutting stones with certain abrasiveness to ensure that the metal of the matrix around the diamond particles is evenly abraded so that the diamond particles are continuously exposed, so as to maintain the sharpness of the impregnated diamond wire saw beads. In order to melt the bond metal powder, it is necessary to use a high temperature of more than 1000 ℃ for heating. At such high temperature, if the temperature is not well controlled, it is easy to reduce the strength of diamond particles, so the manufacturing process of impregnated diamond wire saw beads is relatively complex and difficult to control.

Sintered Diamond Wire Saw Bead

The manufacturing process of sintered diamond wire saw beads is very similar to that of hot-pressed sintered diamond segments. It is a new type of diamond wire saw bead production process improved on the basis of impregnated diamond wire saw bead production process. The production process directly cold-press diamond particles with copper, nickel, diamond, Yi and other binding metal powders into a sintering ring, and heat and pressurize them at a temperature lower than 1000 ℃ under the gas protection environment at the same time. The binding metal is extruded in the molten state, and is tightly bound with diamond particles to form diamond wire saw beads.

Because the hot pressing sintering process with low-temperature gas protection is adopted, the sintering environment is free of oxygen during the whole hot pressing process, which avoids the oxidation of the metal bond. Due to the low solubility of carbon in other metal powders used, the possibility of carbonization (graphitization) of diamond particles during sintering is prevented. By taking effective control measures of low-temperature and low-pressure process parameters, the temperature and pressure of hot pressing can be adjusted to the appropriate value as low as possible to eliminate any damage to the physical and chemical properties of the diamond caused by the hot pressing process. In this way, the firmness of the matrix is maintained without affecting the strength of the diamond.

Adjusting the proportion of different components in the bond or selecting the diamond particle with different strengths and particle sizes can change the wear rate of the bond matrix and the best exposure time of the diamond crystal (cutting edge) to make sintered diamond wire saw beads for different purposes. Compared with the ordinary hot-pressed sintered diamond segment, the hot-pressed sintered diamond wire saw bead ring has a thin thickness, small volume and different shape. The manufacturing cost of sintered diamond wire saw bead is about 30% higher than that of the electroplated diamond wire saw bead of the same size.

Because the manufacturing process and structure are basically the same, sintered diamond wire saw beads and impregnated diamond wire saw beads have some common characteristics. They are the best beading type for cutting granite, sandstone and other hard stones at present. If the sintered diamond bead wire saw or impregnated diamond bead wire saw used to cut hard stone is used to cut soft stone that is easy to be abraded, such as marble, the diamond particles are not easy to expose, the diamond wire saw bead is not sharp or self-sharpening is poor, especially when cutting limestone stone, the cutting sharpness of sintered diamond wire saw bead and impregnated diamond wire saw bead is worse, and the cutting efficiency is very low. However, by adjusting and reducing the hardness and wear resistance of the base metal, sintered or impregnated diamond wire saw beads for cutting soft stone can also be produced, and the service life of this diamond wire saw bead is at least 50% longer than that of the electroplated diamond wire saw bead.

Generally, the cutting speed of the electroplated diamond bead wire saw exceeds that of the sintered or impregnated diamond bead wire saw. With the increase of service time, the cutting speed of the electroplated diamond bead wire saw will gradually decrease and be lower than that of the sintered or impregnated diamond bead wire saw. The cutting speed of the latter will basically remain unchanged, and the cutting life can also exceed twice that of the electroplated diamond bead wire saw. The following table is a comparison of the service life of different soft stones cut by electroplated diamond wire saw beads, sintered diamond wire saw beads or impregnated diamond wire saw beads. Generally, the cutting speed of sintered diamond wire saw beads and impregnated diamond wire saw beads is about 20% lower than that of electroplated diamond wire saw beads.

| Stone Type | Cutting Life of Different Kinds of Diamond Wire Saw Beads/m2·m-1 | |

|---|---|---|

| Electroplated Bead Diamond Wire Saw | Sintered or Impregnated Bead Diamond Wire Saw | |

| Crystal Stone | 25 | 50 |

| Travertine | 50 | 75 |

| Dense Stone | 15 | 30 |

| Hard Marble | – | 15 |

| Volcanic Tuff | – | 22 |

In order to improve the binding force between diamond particles and metal matrix, a surface layer of diamond particles is coated before mixing, so that the diamond particles and other metals(matrix) are more firmly combined during sintering, and the service life of sintered diamond wire saw beads is improved.

When using sintered diamond wire saw beads and impregnated diamond wire saw beads, the sufficient cooling water supply must be guaranteed during the cutting operation. According to the size of the cutting surface, the water supply of 20~50L/min is generally required to ensure that the diamond wire saw is in a reasonable cutting state. However, the cooling water consumption of diamond wire saw using electroplated diamond wire saw beads is only 10-20L/min.

Brazed Diamond Wire Saw Bead

In addition to sintered and electroplated diamond wire saw beads, many enterprises have recently studied and promoted a high-temperature vacuum brazing diamond wire saw bead. The diamond wire saw beads are combined by chemical bonding and metallurgical bonding through high-temperature vacuum brazing, so that the diamond is firmly held on the matrix. Due to the wetting of the brazed solder on the diamond, its matrix shape is concave, so the diamond edge is sharp and high. The height of the diamond edge of the common diamond wire saw bead is about one-third to one-half of that of the diamond, while the height of the diamond edge of the brazed diamond wire saw bead can reach two-thirds. Due to the use of patented technology, brazed diamond is also known as “never falling off”, which can maintain the sharpness of brazed diamond wire saw beads for a long time, so that each diamond can be used to the maximum extent, and the “effective utilization rate” of diamond can be increased from 5% – 10% of the conventional method to more than 50%. Therefore, the cutting efficiency of brazed diamond wire saw beads is 2~3 times higher than that of sintered diamond wire saw beads. When using the brazed diamond bead wire saw to cut stone, the energy consumption of the motor is greatly reduced, for example, the 22kW low-power wire saw machine can exert the cutting efficiency of the high-power wire saw machine above 37 kW.

Another feature of the brazing manufacturing process is to make the diamonds orderly arranged and evenly distributed. The diamond content of diamond wire saw beads is greatly reduced, only one-fifth of the original content is needed, and each diamond can effectively participate in the cutting work, which not only reduces the material cost, but also greatly improves the cutting performance. Because of the orderly and uniform arrangement of diamonds, good chip removal and cooling effect, and stable cutting performance, it will be the replacement of electroplated diamond wire saw beads.

Brazed diamond wire saw beads are usually only suitable for cutting soft stones such as marble and medium-hard granite. It is said that the efficiency of cutting marble with brazed diamond wire saw beads can reach 10~20m2/h, and the service life of brazed diamond wire saw bead per meter is 25~30m2. The price is very advantageous, which can reach the cost of ordinary diamond rope saw below 70%.

The disadvantage of brazed diamond bead wire saw is that the sharpness is greatly improved, the amount of stone removal per unit time is also greatly increased, and the load on the wire rope is also greatly increased. Therefore, the service life of wire rope of brazed bead diamond wire saw is generally lower than that of brazed diamond wire saw bead. It can be repaired by replacing the wire rope. Once the wire rope is found to break frequently, the unused brazed diamond wire saw beads can be removed and re-penetrated into a new wire rope to make a new diamond wire saw for use. Generally, the brazed diamond wire saw beads can be reused for 1-2 times. The statistical results show that the service life of the brazed diamond wire saw bead is longer than that of the wire rope. During the service life of the brazed diamond wire saw bead, the wire rope needs to be replaced repeatedly. For this reason, the brazed diamond bead wire saw usually adopts the spring fixed structure, and rarely uses the plastic injection or rubber injection sealing structure.

In order to stabilize the quality, at present, the problems that need to be further solved in brazed diamond wire saw beads are to further improve and stabilize the manufacturing process, including the selection of brazed solder, the removal of residual adhesive, the low efficiency of manual operation, and the relatively complex ordered arrangement of diamonds, etc., especially the mass and efficient production process methods still need to be solved.

Brazed bead diamond wire saw is a new type of diamond wire saw at present. Its use requirements and conditions are basically the same as those of diamond wire saw with electroplating, plastic injection and other structures. For example, the brazed bead diamond wire saw also has cutting directionality. The movement direction should be the small end in front and the big end in back. It is not allowed to use in reverse. Before connecting into a closed loop, the diamond wire saw should also be preloaded and rotated along its tightening direction to produce the rotation effect in the cutting movement, which is conducive to the uniform wear of the diamond beads. The diamond wire saw per meter of length should rotate counterclockwise for 1~1.5 turns. If the threaded joint is used for connection, the total number of turns of the diamond wire saw should also be increased by 7 additional turns of thread of the threaded joint. For example, the brazed bead diamond wire saw with a rope length of 30m should be rotated counterclockwise for 37-52 turns(30*1+7=37 turns, 30*1.5+7=52 turns).

Brazed bead diamond wire saw is also made of metal materials. Special attention should be paid to rust prevention during use. When not in use, it should be cleaned, dried in the sun, and stored in antirust liquid (oil, diesel mixture).