The application of diamond wire saw involves factors such as the type and hardness of the cutting subjects. Only a proper selection of diamond wire saws can achieve the best cutting effect and the longest service life. Different applications of diamond wire saw have different requirements on the length, diameter and number of diamond beads of diamond wire saw.

According to the cutting process, the cutting of diamond wire saw is divided into mining cutting, shaping cutting, plate processing cutting and special-shaped products processing and cutting.

According to the type of equipment used, diamond wire saw can be divided into diamond wire saw for mobile wire saw machine used for mining, diamond wire saw for fixed wire saw machine used for shaping and plate cutting, diamond wire saw for special-shaped wire saw machine, diamond wire saw for multi-wire saw machine used for plate cutting, and diamond wire saw for concrete removal cutting machine.

Diawe Tools has briefly introduced the application of diamond wire saw. Here we will discuss it in detail.

Diamond Wire Saw for Stone Mining

When mining and cutting stones, the diamond wire saw used is divided into two types: one is used for hard stones, such as cutting granite, and the other is used for soft stones, such as cutting marble, limestone and travertine.

Diamond Wire Saw for Soft Stone Mining

Among the building stones, the most commonly used soft stone is marble. Because the basic composition of marble is calcium carbonate or dolomite, and it does not contain hard mineral components such as quartz and feldspar, it can meet the requirements when mining and cutting with electroplated diamond wire saw. After reasonable adjustment of the formula, the sintered diamond wire saw for cutting soft stone can also be used for mining and cutting marble.

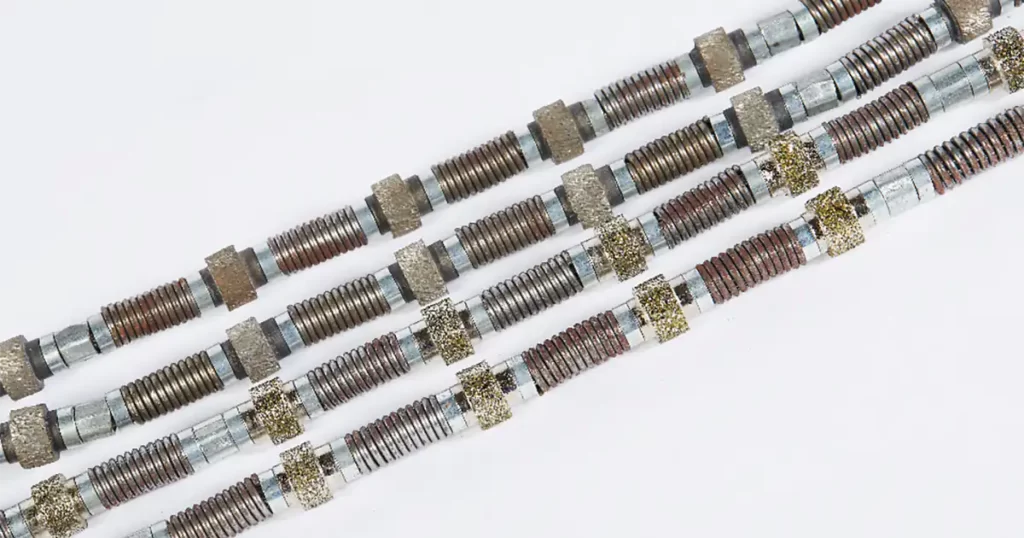

Because of the particularity of marble composition, there is no need to worry about the gap between the diamond beads and the wire rope, which will cause abrasion to the wire rope. Therefore, the most economical diamond wire saw structure in marble, limestone and travertine mines is spring type. This is also the reason why spring type diamond wire saw with electroplated diamond beads is the most widely used in the mining of soft stones such as marble.

With the attention paid to the safety of mining, the plastic injection diamond wire saw with sintered diamond beads has better safety and longer service life is gradually replacing the spring type diamond wire saw with electroplated diamond beads and widely used in the mining of marble mines. In addition, when mining high hardness marble such as serpentine, the use of spring type diamond wire saw with electroplated diamond beads usually cannot achieve the ideal cutting life, while the plastic injection diamond wire saw with sintered diamond beads high wear resistance is the best choice for cutting serpentine stone.

In order to maintain the cutting speed of soft stones such as marble, while taking into account the safety of use, a type of diamond wire saw with electroplated diamond bead using the plastic injection plus spring as the supporting framework, has also been used for mining and cutting of marble, limestone and travertine mines.

Diamond Wire Saw for Hard Stone Mining

When mining granite and sandstone, the diamond wire saw with plastic injection structure must be used. This is not only for the safety, but also to consider its wear resistance. The plastic injection diamond wire saw uses polyurethane plastic with good wear resistance as the fixed spacer between the diamond beads. The gap between the diamond beads and the wire rope is filled with plastic. The diamond beads and the wire rope cannot rotate relative to each other to prevent the quartz and feldspar particles in the sawdust from entering between the diamond beads and the wire rope, which will cause abrasion and damage to the wire rope.

The manufacturing process and selected metal bond of hot-pressed diamond beads are similar to that of hot-pressed diamond segments. Sintered diamond beads have good wear resistance, and the metal bond can withstand the abrasion of hard components such as quartz in granite. Because the hardness range of granite is large, the diamond wire saw for cutting different hardness materials and wear properties can be made by adjusting the proportion of different metal components in the bond, selecting different strengths and particle sizes of diamond, changing the wear speed of the bond matrix and the best exposure time of diamond crystal.

However, the spring-type diamond wire saw with electroplated diamond beads has a thin diamond coating and poor wear resistance of the base metal, which cannot withstand the abrasion of high-hardness quartz in granite. If cutting granite with the electroplated diamond wire saw, the service life of the diamond beads is very low. What’s more, quartz particles can easily enter the space between diamond beads, washers or springs and wire ropes, which will break the fine wire core rope, reducing the strength of the whole wire rope, and the whole wire rope will be broken in a short time.

The following table is the statistical data of cutting efficiency and service life of diamond wire saws when mining different kinds of stones. When cutting hard stones such as granite, the plastic injection diamond wire saw with sintered diamond beads is used. When cutting soft stones such as marble and limestone, the spring or plastic injection diamond wire saw with electroplated diamond beads is used.

| Statistics of Cutting Efficiency and Service Life of Diamond Wire Saws Mining and Cutting Different Stones | |||||

|---|---|---|---|---|---|

| Stone Product Name | Cutting Efficiency/m2·h | Life of Diamond Wire Saw/m2·m-1 | Stone Product Name | Cutting Efficiency/m2·h | Life of Diamond Wire Saw/m2·m-1 |

| English Sandstones(hard) | 4-13 | 8-24 | Candoglia(soft) | 13 | 33-35 |

| Cinzento(hard) | 5.5 | 9 | Passau(hard) | 1.5 | 3.5 |

| Tcino Gneiss(hard) | 4 | 6 | Rosa Porrino(hard) | 3 | 5.5 |

| Pietra Screa(soft) | 9 | 10-12 | Canadian Black(hard) | 5 | 10.5 |

| Santafiora(soft) | 7 | 50-60 | Impala(hard) | 6 | 9-10 |

| Verde Alpi(soft) | 8 | 18 | Finale Stone(soft) | 14 | 21 |

| Baltic Brown(hard) | 4 | 7.5 | Dakota Mahogany(hard) | 2 | 2.5 |

| Grigio Perla(hard) | 1.5 | 6.5 | Lanhelin(hard) | 2.5 | 4 |

| Rosa Baveno(hard) | 6.5 | 3.5 | Serizzo(hard) | 3.5-4 | 6-7 |

| Chiandone Limbara(hard) | 3.5 | 6 | Alta Quarzite(hard) | 5 | 3 |

| Pale Labrador(hard) | 5.5 | 9 | Delabole Slate(hard) | 4.7 | 8 |

| Dark Labrador(hard) | 6 | 13-17 | Diorite(hard) | 3 | 9 |

| Australian Sandstones Average(soft) | 6.5-18 | 12-45 | Juparana(hard) | 3 | 6 |

| Vicenza Stone(soft) | 10 | 100-110 | Bianco Crystal(hard) | 2.5 | 6 |

| Palissandro(soft) | 12 | 28-30 | Azul Platino(hard) | 3 | 6 |

| Tivoli Travertine(soft) | 15.5 | 90-100 | Peperino(soft) | 15-17 | 14-16 |

| Aberllefenni(hard) | 2-4 | 5-6 | Brecce(soft) | 7-9 | 13-15 |

| Ardesia(hard) | 6-8 | 9-11 | Ceppo(soft) | 5-8 | 10-15 |

| Delabole Blue Grey(hard) | 4-7 | 8 | Pietra Serena(hard) | 4 | 5 |

| Festiniog Blue(hard) | 4 | 6 | Arlanza Sandstone(soft) | 18-20 | 8-9 |

| Kirkstone Veneto(soft) | 9 | 9-18 | Jadeite Green(hard) | 2 | 6 |

| Trachite Veneto(hard) | 3 | 6 | |||

Diamond Wire Saw for Rough Stone Block Shaping and Cutting

The fixed diamond wire saw shaping machine is the most widely used rough stone block shaping machine at present, and it is also the equipment for cutting and producing stone plates of different thicknesses. Whether it is cutting granite or marble, the plastic injection diamond wire saw with sintered diamond beads is the most suitable diamond wire saw for fixed wire saw machines used in shaping and plate cutting.

For the use of mobile wire saw machine, the operation site is generally relatively open, and the operators are relatively scarce and scattered. If the protective measures are appropriate, the operators shall operate in strict accordance with the operating procedures. When mining marble, the safety of using spring-type diamond wire saw is relatively high.

The diamond wire saw shaping machine is usually fixed and installed, especially the diamond wire saw shaping machine used for cutting plates in the stone processing plant/factory. Compared with the mining operation site, it is generally installed in a relatively narrow site space, and some are even installed in the workshop. If a spring-structured diamond wire saw is used, once the diamond wire saw breaks (this will certainly happen), there will be about 9 to 15 parts in the fixed unit near the fracture, which will fly out of order at a linear speed of 25-40m/s. Even if the corresponding protective measures are taken, these flying diamond wire saw parts, for the personnel working in the relatively narrow processing workshop, Sometimes it still poses a threat or even harm.

Although the spring-type electroplated diamond wire saw is the earliest diamond wire saw used for rough marble block shaping and plate cutting, in order to reduce or eliminate the potential safety hazards caused by the breaking of this type of diamond wire saw, it is recommended that the plastic injection diamond wire saw with sintered or electroplated diamond beads should be selected for the rough marble block shaping and plate cutting, the plastic injection diamond wire saw with sintered diamond beads should be selected for the granite block shaping and plate cutting.

The following table is the statistical table of the cutting efficiency and service life of the fixed diamond wire saw cutting stone plates/slabs.

| Statistics of Cutting Efficiency and Service Life of Fixed Diamond Wire Saw | |||

|---|---|---|---|

| Stone Product Name | Cutting Efficiency/m2·h | Life of Diamond Wire Saw/m2·m-1 | Number of Diamond Beads/pcs·m-1 |

| Baveno Bianco | 2 | 11 | 40 |

| Baveno Rosa | 1.5 | 10 | 40 |

| Bianco Montorfano | 1.5 | 11 | 40 |

| Pietra di Lusema | 2-2.5 | 9 | 40 |

| Serizzo | 2-2.5 | 16 | 40 |

| Trachite Veneto | 1.5 | 7 | 40 |

| Peperino | 3-3.5 | 18-20 | 30 |

| Trachite Veneto | 2 | 10 | 40 |

| Granit du Tam | 1.4-2 | 11-15 | 40 |

| Granit des Cretes | 1.2 | 12-14 | 40 |

| Piedra Galicia | 2-2.5 | 12-15 | 40 |

| Ballyknockan Grey | 1.2 | 13-14 | 40 |

| Wicklow Grey | 1.2 | 30-33 | 40 |

| Bianco Castilla | – | – | 40 |

Diamond Wire Saw for Cutting Special-shaped Stone

The main technological parameters that need to be controlled during the use of the CNC diamond wire saw for processing special-shaped stones are the linear speed and cutting feed speed of the diamond wire saw. The linear speed of the diamond wire saw is related to the variety, hardness and wear of the stone. The cutting feed speed is not only related to the variety, hardness, shape and other parameters of the processed stone, but also related to the length of the cut products, the working current of the main motor and other factors. The service life of diamond wire saw is related to the above parameters, the structure of the diamond wire saw and the type of diamond bead.

Because the cutting track of the diamond wire saw changes a lot when cutting special-shaped stones, and the stress condition of the diamond wire saw is complex when cutting, its cutting conditions are not better than that of shaping cutting, and sometimes even worse than that of mining and cutting, so when cutting special-shaped stones, the cutting efficiency of the CNC wire saw machine and the service life of the diamond wire saw will be reduced.

Diamond wire saw machine is a kind of stone processing equipment using flexible cutting tools. Its cutting efficiency is lower than that of diamond circular saw blade/disc. One-sided pursuit of high cutting efficiency often leads to diamond wire saw easy to break, blunt or shorten its service life, and also reduces the accuracy of processing stone products. These use characteristics of fixed-wire saw machines must attract the attention of users.

When cutting special-shaped stone, the machining advantage of the CNC wire saw machine is that it can realize the processing of various complex shapes and patterns that cannot be realized by other processing equipment and processing methods, or it is difficult to realize them, such as solid columns, hollow columns, a group of spiral curve stairs processed, tombstones with any curve profile, and special shaped columns, cones and spiral columns from the same piece of rough stone block.

When CNC wire saw machine is used to process special-shaped stone of simple shape, its cutting efficiency is sometimes lower than that of the processing equipment using rigid cutting tools such as gang saw or saw blade, and the deviation of the processed products may also be relatively large. However, if it is to process special-shaped stone products with complex shapes, other equipment sometimes cannot complete the processing or requires a long processing time to complete the processing, while the CNC wire saw machine can easily process the stone products with complex shapes, which is also the processing advantage of the CNC wire saw machine that cannot be compared with other equipment.

When selecting diamond wire saw to process special-shaped stone, in addition to considering its production efficiency, its special cutting function should be taken as the basis for selection. Stone products that can be produced with general equipment should not be processed with diamond wire saw as far as possible to achieve the best economic benefits.

Because the cutting accuracy of special-shaped stone is required to be high, the diamond wire saw needs to be applied with relatively large tension, so the requirements for the movement accuracy and cutting accuracy of the fixed CNC wire saw machine are very high. Therefore, the plastic injection diamond wire saw with sintered diamond beads is recommended for the processing of marble or granite special-shaped products, which also ensures the safety of use.

The following table shows the relationship between cutting efficiency, linear speed of diamond wire saw and tension value when cutting different kinds of special-shaped stones with CNC wire saw machine.

| Cutting Efficiency and Linear Speed of Diamond Wire Saw Cutting Different Kinds of Special-shaped Stones | ||||

|---|---|---|---|---|

| Stone Product Name | Linear Speed of Diamond Wire Saw/m·s-1 | Cutting Efficiency/m2·h-1 | Service Life/m2·m-1 | Value of Tension |

| I, II Grade Granite | 23-28 | 0.3-0.6 | 45087 | The tension value is 3500N, and the indication range of the hydraulic system pressure gauge is 3500-4000N. |

| Ⅲ、Ⅳ、Ⅴ Grade Granite | 20-24 | 0.3-0.6 | 4~8 | |

| Soft Marble | 30-35 | 1.0-2.0 | 30-40 | |

| Hard Marble | 28-32 | 0.7-1.5 | 20-30 | |

| Limestone | 30-35 | 1.0-2.0 | – | |

| Hard Limestone | 28-32 | 0.7-1.5 | 40-60 | |

| Travertine | 34-40 | 1.5-3.0 | 40-60 | |

The following table shows the relationship between the cutting efficiency, feed speed and the cutting length of stone when the diamond wire saw is used to process special-shaped stone products.

| Cutting Length/m | Cutting Efficiency of Diamond Wire Saw Cutting Different Special-shaped Stones/m2·h-1 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.8 | 1 | 1.2 | 1.4 | 1.6 | 1.8 | 2 | 2.2 | |

| Feed Rate of Diamond Wire Saw/m·h-1 | |||||||||||||

| 0.3 | 0.67 | 1.00 | 1.33 | 1.67 | 2.00 | 2.67 | 3.33 | 4.00 | 4.67 | 5.33 | 6.00 | 6.67 | 7.33 |

| 0.4 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 | 3.50 | 4.00 | 4.50 | 5.00 | 5.50 |

| 0.5 | 0.40 | 0.60 | 0.80 | 1.00 | 1.20 | 1.60 | 2.00 | 2.40 | 2.80 | 3.20 | 3.60 | 4.00 | 4.40 |

| 0.6 | 0.33 | 0.50 | 0.67 | 0.83 | 1.00 | 1.33 | 1.67 | 2.00 | 2.33 | 2.67 | 3.00 | 3.33 | 3.67 |

| 0.7 | 0.29 | 0.43 | 0.57 | 0.71 | 0.86 | 1.14 | 1.43 | 1.71 | 2.00 | 2.29 | 2.57 | 2.86 | 3.14 |

| 0.8 | 0.25 | 0.38 | 0.50 | 0.63 | 0.75 | 1.00 | 1.25 | 1.50 | 1.75 | 2.00 | 2.25 | 2.50 | 2.75 |

| 0.9 | 0.22 | 0.33 | 0.44 | 0.56 | 0.67 | 0.89 | 1.11 | 1.33 | 1.56 | 1.78 | 2.00 | 2.22 | 2.44 |

| 1.0 | 0.20 | 0.30 | 0.40 | 0.50 | 0.60 | 0.80 | 1.00 | 1.20 | 1.40 | 1.60 | 1.80 | 2.00 | 2.20 |

| 1.2 | 0.17 | 0.25 | 0.33 | 0.42 | 0.50 | 0.67 | 0.83 | 1.00 | 1.17 | 1.33 | 1.50 | 1.67 | 1.83 |

| 1.3 | 0.15 | 0.23 | 0.31 | 0.38 | 0.46 | 0.62 | 0.77 | 0.92 | 1.08 | 1.23 | 1.38 | 1.54 | 1.69 |

| 1.4 | 0.14 | 0.21 | 0.29 | 0.36 | 0.43 | 0.57 | 0.71 | 0.86 | 1.00 | 1.14 | 1.29 | 1.43 | 1.57 |

| 1.5 | 0.13 | 0.20 | 0.27 | 0.33 | 0.40 | 0.53 | 0.67 | 0.80 | 0.93 | 1.07 | 1.20 | 1.33 | 1.47 |

| 1.6 | 0.13 | 0.19 | 0.25 | 0.31 | 0.38 | 0.50 | 0.63 | 0.75 | 0.88 | 1.00 | 1.13 | 1.25 | 1.38 |

| 1.7 | 0.12 | 0.18 | 0.24 | 0.29 | 0.35 | 0.47 | 0.59 | 0.71 | 0.82 | 0.94 | 1.06 | 1.18 | 1.29 |

| 1.8 | 0.11 | 0.17 | 0.22 | 0.28 | 0.33 | 0.44 | 0.56 | 0.67 | 0.78 | 0.89 | 1.00 | 1.11 | 1.22 |

| 1.9 | 0.11 | 0.16 | 0.21 | 0.26 | 0.32 | 0.42 | 0.53 | 0.63 | 0.74 | 0.84 | 0.95 | 1.05 | 1.16 |

| 2.0 | 0.10 | 0.15 | 0.20 | 0.25 | 0.30 | 0.40 | 0.50 | 0.60 | 0.70 | 0.80 | 0.90 | 1.00 | 1.10 |

Generally, the longer the rough stone block is, the lower the cutting feed rate is. The harder the stone is, the lower the cutting efficiency is, and the lower the cutting feed rate is. Before processing a certain kind of stone, you should first understand the cutting performance of this kind of stone, and then through the above two tables, machine operators can basically determine the reference range of the feed speed of the diamond wire saw when cutting special-shaped stones of different lengths. In the table above, Diawe Tools provides the cutting efficiency values of a few stone varieties for reference. But in production practice, attention should be paid to accumulating the specific processing parameter data of various stones, so as to expand the range of use.

In addition, the method of alternately cutting soft and hard stones can not only improve the sharpness of the diamond wire saw, but also improve its service life.

Diamond Multi-wire Saw for Cutting Stone Slabs

The diamond multi-wire saw used for stone slabs(or called stone plates) processing uses sintered diamond beads and plastic injection structure. The main competitive producing process of diamond multi-wire saw machines for stone slab processing is the frame saw machine, that is, the sand saw for granite slab processing and the row saw for marble slab processing. The cutting speed of the diamond multi-wire saw is faster than the frame saw machine. Besides, the main competitive advantage is the discharge rate of the rough stone block, that is, the size of the cutting seam.

In the early stage, limited by the manufacturing process of diamond wire saw, the diameter of diamond wire saw is generally more than 8.5 mm. Compared with the sand saw with a thickness of only about 7.2mm, the saw gap of this width will cause a stone waste. However, at present, the diamond multi-wire saw supporting the cutting of granite adopts the diamond wire saw with a diameter of 7-7.2 mm sintered diamond bead and plastic injection structure, which can fully compete with the sand saw.

In cutting marble, the width of the saw gap of the gang saw is about 5.3-5.5mm, and some of them are only 4.2-4.5mm wide. If the diamond wire saw with a diameter of 7.2mm is still used, the stone loss in the cutting gap will be much. It can be considered to use the plastic injection structure & electroplated diamond beads, the diamond wire saw with a diameter of 6mm, and the diamond multi-wire saw for cutting marble slabs.

The short length diamond multi-wire saw generally adopts the jointless closed-loop structure. It adopts the method of disassembling the steel wire at the wire rope and then re-connecting to form a jointless closed loop diamond wire saw. The overall life of the diamond wire saw without a connector can be improved much.

For the diamond multi-wire saw with a long length, the open structure is generally adopted, and the new rope is allowed to have a connector. After 80~100 hours of use, the new connector must be replaced to prevent the fracture of the connector due to fatigue and wear.

Table Diamond Wire Saw for Cutting Marble Slabs

The table diamond wire saw is mainly used for cutting small stone products such as stone mosaic, so it is recommended to use the plastic injection diamond wire saw with electroplated beads with a diameter of 6 mm for cutting soft stone products such as marble. If it is necessary to cut granite and other hard stone products, it is recommended to use other cutting methods, or use the plastic injection diamond wire saw with sintered beads with a diameter of 7.2mm.

Diamond Wire Saw for Cutting Concrete

Although the hardness and compactness of concrete are not as good as that of stone, especially as hard as granite, many concrete is added with a certain density of steel mesh, and the diameter of many steel bars even reaches 20~30mm. When dismantling such reinforced concrete components, diamond wire saw must have relatively high strength and cutting performance. Therefore, the relatively hard base metal sintered diamond beads and the diamond wire saw with spring and plastic injection structure are the ideal diamond wire saw for removing reinforced concrete.

When cutting some plain concrete, masonry and other structural members without reinforcement, the diamond wire saw made of electroplated diamond beads with high sharpness and plastic injection with spring can be used. The diamond wire saw directly injected with sintered diamond beads can also be used for the removal of components such as plain concrete.

The diamond wire saw for concrete cutting per meter is usually installed with more than 40 diamond beads.

The rubber injection diamond wire saw is mainly used in stone mines in cold regions with a temperature of about 0 ℃, and can also be used in concrete component removal.

Conclusion

Different applications of diamond wire saw have different performance requirements for diamond wire saw. After the above discussion, we summarized the technical parameters of diamond wire saw applicable to various application scenarios.

| Summary of Technical Parameters of Diamond Wire Saw for Different Applications | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Applications | Mining & Quarrying | Rough Stone Block Shaping | Special-shaped Stone Cutting | ||||||

| Parameters | Unit | Hard Marble | Limestone and Travertine | Granite | Hard Marble | Limestone and Travertine | Granite | Hard Marble | Granite |

| Structure of Diamond Wire Saw and Number of Diamond Beads | Structure Type/Number of Diamond Beads Per Meter | Plastic Injection structure/30 Spring structure/29 |

Plastic Injection structure/40 | Plastic Injection structure/30 Spring structure/29 |

Plastic Injection structure/40 | ||||

| Outer Diameter of Diamond Bead | mm | 11 | 11.4 | 11 | 11.2 | 8.7 | |||

| Dimension of Diamond Bead Framework (Outer Diameter * Length * Inner Diameter) | mm*mm*mm | 8*10*5.2 | 8*10*5.2 | 6*9*4 | |||||

| With 1/4 Thread or Without Thread | With 1/4 Thread | With 1/4 Thread or Without Thread | With 1/4 Thread | With M4-5 Thread | |||||

| Length of Diamond Layer | mm | 7 | |||||||

| Diamond Concentration | Carat Per Diamond Bead | 0.5 | 0.6 | 0.55 | 0.65 | 0.5 | 0.45 | ||

| Minimum Service Life | m2/m | 18-20 | Dense Limestone 45-55, Travertine 70-80 |

Grade 1-2 Granite 8-11, Grade 3-5 Granite 5-8 |

25-30 | Dense Limestone 80-90, Travertine 100-130 |

Grade 1-2 Granite 10-11, Grade 3-5 Granite 8-10 |

28-32 | Grade 1-2 Granite 8-10, Grade 3-5 Granite 6-8 |

| Cutting Speed | m2/h | 7-9 | Dense Limestone 10-14, Travertine 12-18 |

Grade 1-2 Granite 3-5, Grade 3-5 Granite 3-4 |

4-5 | Dense Limestone 4-5, Travertine 4-5 |

Grade 1-2 Granite 2-3, Grade 3-5 Granite 1-3 |

3-4 | Grade 1-2 Granite 4-5, Grade 3-5 Granite 2-4 |

| Recommended Optimum Linear Speed | m/s | 32-36 | 30-40 | 20-25 | 32-36 | 30-40 | 20-25 | 30-35 | 20-25 |

| Recommended Diamond Wire Saw Structure and Number of Diamond Beads | Structure Type/Number of Diamond Beads Per Meter | Plastic Injection Structure/37 or Spring Structure 28/31/32 | Plastic Injection Structure/35-37 | Plastic Injection Structure/37 or Spring Structure 28/31/32 | Plastic Injection Structure/37 | – | – | ||