At present, the diamond wire saw is one of the most modern tools for stone quarrying and processing. With the improvement of environmental protection requirements, the advantages of diamond wire saws have become more obvious, and they have become one of the necessary tools for the stone industry.

Diawe is equipped with an advanced diamond wire saw automated production line, using the latest production technology and unique material technology. The diamond wire saw produced has the following characteristics:

- Adopt special formula and structure design, suitable for different types of stone processing.

- Industry-leading manufacturing technology effectively guarantees stable product quality.

- The product is safe, efficient, energy-saving and environmentally friendly.

Diamond Bead for Wire Saw

The diamond bead is the most basic unit of the diamond wire saw, and it is the grinding part during the operation. According to different cutting objects, there are various diameter specifications, number of beads per meter and production processes.

Sintered Bead

The sintered bead is suitable for quarrying and processing all kinds of marble, granite, sandstone, etc.

Electroplated Bead

The electroplated bead is used for the quarrying and processing of marble.

Soldered and Brazed Bead

Soldered and brazed beads can quarry and process marble when there is no or just a little water, or under freezing conditions.

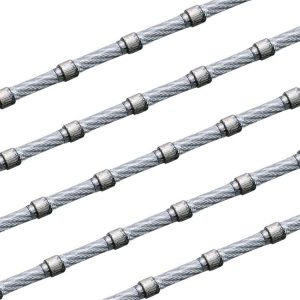

Diamond Wire

On the basis of diamond beads, different types of wire saws are developed according to different injection molding, joining processes and operating environments.

Rubber-Fixed Wire Saw

The rubber-fixed wire saw is used for quarrying and processing marble, granite, sandstone, etc.

Plastic-Fixed Wire Saw

The plastic-fixed wire saw is used for processing marble, granite, quartz and artificial stone.

Spring-Fixed Wire Saw

The spring-fixed wire saw is used for quarrying soft marble.

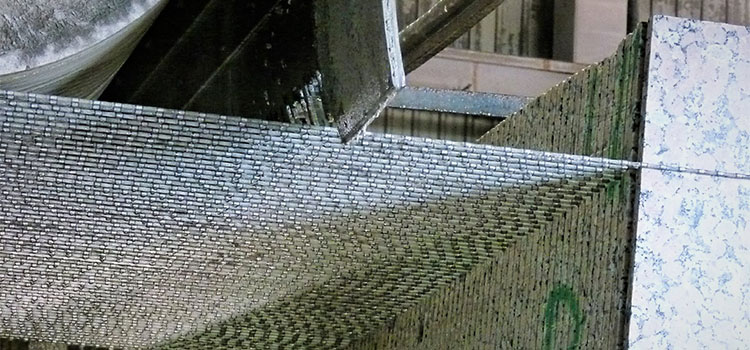

Diamond Multi-Wire Saw

The diamond multi-wire saw is used for cutting blocks of marble, granite and sandstone. The multi-wire has the advantages of high efficiency (10 – 16 times more efficient cutting), low risk of breakage, long service life, smooth sawing surfaces, energy-saving and environmental protection.

The Specifications of the Multi-Wire Saw

| Type | Diameter(mm) | Number of Beads/Meter | Fixed Way | Efficiency(m²/h) | Service Life(㎡/m) | Line Speed(m/s) |

|---|---|---|---|---|---|---|

| Diamond Multi-Wire Saw | Φ5.3 | 37/36 | Plastic | 0.8 – 1.0 | 5 – 7 | 26 – 30 |

| Φ6.3 | 0.8 – 1.1 | 6 – 10 | 26 – 30 | |||

| Φ7.3 | 0.8 – 1.3 | 8 – 14 | 26 – 30 | |||

| Φ8.2 | 0.8 – 1.4 | 12 – 15 | 26 – 30 |

Diamond Wire for Quarrying

Compared with the traditional blasting of mountains with explosives, the biggest advantage of the wire saw used in quarrying is the high forming rate of stone.

Wide Range of Using

Suitable for separation and cutting of all kinds of marble, granite, sandstone and other stones

Application Scenarios

It can be used for open-pit quarrying, narrow ore veins working and underground mining with explosion hazards.

Value-added Advantages

It has the characteristics of safety, high efficiency, energy-saving and environmental protection.

Diamond Wire Saw for Granite Quarrying

The diamond beads for granite quarrying are strictly fitted with rubber and wire and have good adhesion. The quarrying wire saw can withstand more shocks and high-temperature operations when working, even work in water-deficient environments. It can be used for smaller radii of curvature to mine larger size stone blocks and is usually used in a wire saw machine with a power of 38-120kw to mine mines at a water flow of 25-50L/min.

| Type | Diameter(mm) | Number of Beads/Meter | Fixed Way | Efficiency(m²/h) | Service Life(㎡/m) | Line Speed(m/s) |

|---|---|---|---|---|---|---|

| Granite Quarrying Wire | Φ11.5 | 40 | Rubber | 20 – 30 | 25 – 35 | 28 – 33 |

| Φ12.5 | 10 – 15 | 10 – 15 | 28 – 30 |

Diamond Wire Saw for Marble Quarrying

Because marble is softer and less difficult to mine than granite, spring wire and plastic injection wire can also be used in addition to rubber injection wire. Using a wire saw to mine marble can effectively reduce the internal damage to the marble block.

| Type | Diameter(mm) | Number of Beads/Meter | Fixed Way | Efficiency(m²/h) | Service Life(㎡/m) | Line Speed(m/s) |

|---|---|---|---|---|---|---|

| Marble Quarrying Wire | Φ11 | 28/30/40 | Spring | 5 – 10 | 13 – 30 | 35 – 42 |

| Φ11 | 37/40 | Plastic and Spring | 8 – 18 | 15 – 40 | 35 – 42 | |

| Φ11.5 | 38/40 | Rubber and Spring | 12 – 20 | 32 – 60 | 35 – 42 |

Diamond Wire for Block Dressing

After the blocks are quarried from the mine, they need to be further processed into stone slabs in the stone processing plant. The use of block dressing/shaping wires to cut and square various types of marble, granite, artificial stone, etc. can improve the added value of products, production efficiency, the quality of slabs, and reduce processing costs.

| Type | Diameter(mm) | Number of Beads/Meter | Fixed Way | Efficiency(m²/h) | Service Life(㎡/m) | Line Speed(m/s) |

|---|---|---|---|---|---|---|

| Marble Block Dressing Wire | Φ9 | 30/33 | Plastic | 1.5 – 2.5 | 25 – 40 | 30 – 40 |

| Φ10.5 | 30/33 | 1.5 – 2.5 | 30 – 45 | 30 – 40 | ||

| Granite Block Dressing Wire | Φ9 | 37 | 0.8 – 1.1 | 8 – 10 | 26 – 28 | |

| Φ10.5 | 37 | 1.0 – 1.3 | 10 – 16 | 26 – 30 | ||

| Φ11 | 37/40 | 1.3 – 2.0 | 12 – 20 | 26 – 32 |

Diamond Wire for Profiling

The special-shaped, concave and convex profiling wire is suitable for flexible processing of various types of marble, granite, artificial stone and other stone curved plates and special-shaped surfaces.

| Type | Diameter(mm) | Number of Beads/Meter | Fixed Way | Efficiency(m²/h) | Service Life(㎡/m) | Line Speed(m/s) |

|---|---|---|---|---|---|---|

| Marble Profiling Wire | Φ8.5/Φ9 | 33 | Plastic | 1.3 – 2.8 | 26 – 43 | 30 – 45 |

| Granite Profiling Wire | 37 | 0.8 – 1.1 | 8 – 10 | 26 – 28 |

the Accessories of Diamond Wire Saw

In addition to ropes and beads, the composition of diamond wire also includes joints and the hydraulic clamp is also used in the process of use. These are essential accessories for a diamond wire saw.