Diamond tools can be classified into four categories based on diamond inlay method, working method, manufacturing method, and application industries.

Ⅰ Categories of Inlay Methods

The inlay methods of diamond tools can be divided into two categories, including surface inlay and inner inlay.

Single crystal particles or polycrystalline sintered bodies are embedded on the tool body in a pre-designed position, which is called a surface inlay.

The tool formed by consolidating or sintering single crystal particles with adhesives (such as metals, resins, ceramics, etc.) into a cutting segment and creating it in one or multiple steps with the tool body is called an inner inlay.

Most diamond tools on the market are inner inlay tools.

Ⅱ Categories of Working Methods

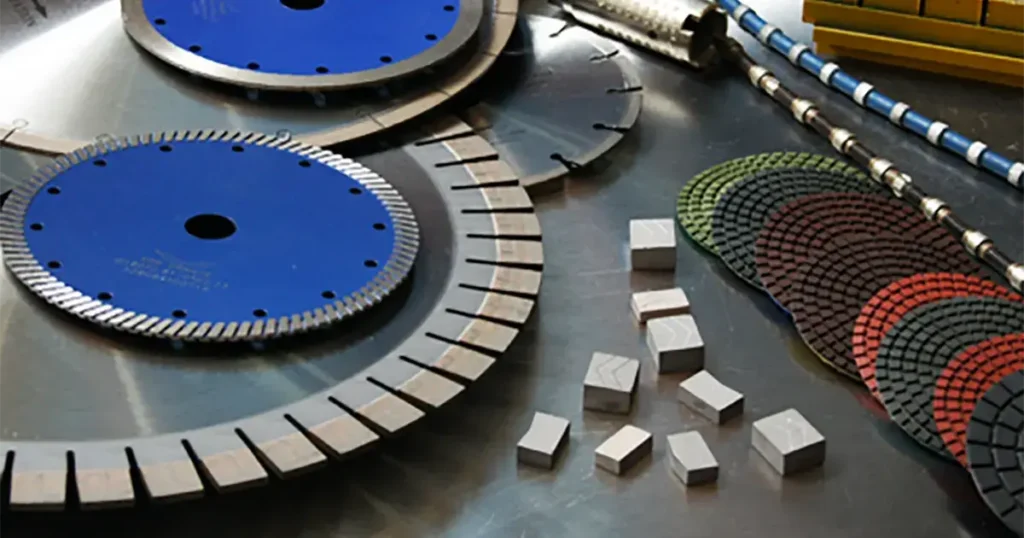

According to the classification of working methods, diamond tools have three major working methods: cutting, drilling, and polishing.

The following are the main diamond tools used for cutting hard and brittle non-metallic materials and metal materials. The former is used for cutting hard and brittle non-metallic materials, including stone, building materials, concrete, asphalt, refractory materials, etc., while the latter is used for cutting metal materials such as semiconductor silicon, aluminum alloys, magnesium alloys, etc.

| Diamond Cutting Tools | |

|---|---|

| Diamond Tools for Cutting Hard and Brittle Non-metallic Materials | Diamond Tools for Cutting Metal Materials |

| Diamond Saw Blades | Diamond Saw Blades |

| Diamond Gang Saw | Polycrystalline Diamond Cutting Tools (Turning, Milling, Planing, Boring, Drilling, etc.) |

| Diamond Wire Saw | Diamond Rope Saw |

| Diamond Band Saw | – |

The following are diamond tools for drilling, including geological exploration drill bits, oil and gas coal drilling drill bits, construction/engineering drilling drill bits, other drilling drill bits, etc.

| Diamond Drilling Tools | |

|---|---|

| Drilling Objects | Tools |

| Geological Drilling | Single Pipe Drilling Bit Double Pipe Drilling Bit Rope Core Drilling Bit Mud Drilling Bit Air Blowing Drilling Bit Comprehensive Drilling Bit Special Drill Bit |

| Oil and Gas Coalfields Drilling | Fully Drilling Bits Core Drilling Bits Specialized Drilling Bits |

| Construction/Engineering Drilling | Core Drilling Bit Non Core Drilling Bit |

| Other Drilling Objects | Stone Drilling Bits Glass Drilling Bits Ceramic Drilling Bits Refractory Material Drilling Bits |

The following are diamond tools used for grinding, polishing, and correction.

| Diamond Polishing Tools | ||

|---|---|---|

| Grinding | Polishing | Correcting |

| Grinding Wheel Grinding Disc Grinding Block Grinding Roller Grinding Cup |

Polishing Agent Polishing Powder Polishing Paste |

Correcting of Grinding Wheel Correcting Pen Assorted Tools |

Ⅲ Categories of Manufacturing Methods

Usually, diamond tools consist of two main parts: the working segments and the tool’s body/blank. The working segments and the tool body can be produced together or separately and then connected together.

The following are the main manufacturing methods for single-crystal inner inlay diamond tools.

| the Manufacturing Methods of Diamond Tools | |

|---|---|

| Manufacturing Methods | Basic Principles |

| Cold Pressing Sintering Hot Pressing Sintering |

Solid Phase Sintering Reaction Process |

| Impregnation Brazing |

Liquid Phase Solidification Encapsulation Process |

| Electroplating | Positive and Negative Ion Deposition Encapsulation Process |

Hot pressing sintering has been widely used among these five diamond tool manufacturing methods. The hot pressing sintering method can place working segments and the tool body in the machine together, to produce tools at once, such as hot pressing circular saw blades, hot pressing drill bits, etc. But more widely used is producing the working segments and tool body separately, after the two main parts are ready, then connecting them by welding or bonding. Welding is widely used, including brazing, laser welding, gas welding (rarely used), etc., while bonding is less commonly used.

The cold pressing sintering method and hot pressing sintering method mainly involve solid-state sintering reactions between binders and between binders and diamonds, sometimes with a small amount of liquid phase present.

The impregnation method and brazing method are essentially the same, which is a liquid-phase solidification encapsulation process that melts the bonding material (which can be in the form of flakes, powders, or blocks) to embed diamond.

As for the electroplating method, it is a process in which the positive and negative ions in the electrolyte are captured and deposited on the electrode by the negative and negative electrodes respectively. It is the only non-heating production process among these five methods that does not cause thermal damage to diamonds.

Polycrystalline diamond tools are composed of three basic components that can currently be produced. The names, process characteristics, and organizational characteristics of these three basic components are as follows.

| Three Basic Components of Polycrystalline Diamond | ||

|---|---|---|

| Name of Polycrystalline Component | Process Characteristics | Structure Characteristics |

| Substrate Free Polycrystalline Diamond(PCD) | Single crystal particles sintered or bonded under high temperature and pressure, without substrate | The structure of single crystal particles sintered directly or by bonding agents |

| Substrate Polycrystalline Diamond Composite(PDC) | Single crystal particles sintered or bonded under high temperature and pressure, with a substrate | The structure of single crystal particles sintered directly or by bonding agents |

| Chemical Vapor Deposition(CVD) | Gas phase reaction at room temperature, deposition and polymerization of new diamond with or without substrate | Sawn structure of newly generated pure diamond through gas-phase reaction |

PCD and PDC are usually embedded on the tool body for use, and the vast majority of oil and gas well drilling bits are embedded with these two components according to the design part of the drill bit. Another important application of PCD and PDC is the processing of non-ferrous metals, such as aluminum alloys, titanium alloys, magnesium alloys, etc. The combination cutting tools made of PCD and PDC can be used for precision and high-speed processing of non-ferrous metals through machining methods such as turning, milling, planing, and boring. It can be foreseen that PCD and PDC will be important machining tools in modern advanced machining centers such as CNC, FMS, and CIM. The combination drawing die made of PCD and PDC greatly improves work efficiency and drawing quality compared to using hard alloy.

CVD has almost the same performance as single crystal diamond, especially with the current development of thick film CVD, which greatly promotes its application in cutting tools, wire drawing molds, grinding wheel correction tools, and other fields. In addition, substrate free multi body components sintered and bonded with copper and other materials with high thermal conductivity, generalized PCD and CVD films have unparalleled high thermal conductivity compared to other materials. In modern times, as thermal dissipative (or heat sink) materials, they have broad application prospects in the manufacturing of electronic devices.

Ⅳ Categories of Application Industries

Diamond tools are currently widely used in various industries and have become an irreplaceable specialized tool in machining. Diawe Tools roughly summarizes the diamond tools involved in various industries in the following table.

| Diamond Tools Used in Various Industries | ||

|---|---|---|

| Application Industry | Suitable Diamond Tools | |

| Resource Exploration | Exploration of Solid Mineral Deposits | Inlaid Geological Drill Bit and Reamer |

| Drilling of Oil and Gas Wells (Onshore and Offshore) | PCD and PDC Inlaid Drill Bit | |

| Coalfield Drilling | Inlaid Coalfield Drill Bit | |

| Groundwater Resource Drilling | Normal Inlaid Drill Bit | |

| Mining | Quarry Mining | Diamond Wire Saw, Diamond Segment |

| Coal Mining | PCD and PDC Inlaid Excavators | |

| Stone Processing | Marble Processing | Diamond Saw Blade, Diamond Frame Saw, Diamond Wire Saw, Band Saw, Diamond Polishing Tools, Diamond Drill Bit, Special-shaped Tools |

| Granite Processing | Diamond Saw Blade, Diamond Wire Saw, Diamond Polishing Tools, Special-shaped Tools, Diamond Drill Bit | |

| Building Materials Processing | Artificial Porcelain Processing | Grinding and Polishing Tools, Special-shaped Tools, Diamond Saw Blade, Core Drill Bit |

| Artificial Ceramic Processing | Grinding and Polishing Tools, Special-shaped Tools, Diamond Saw Blade, Core Drill Bit | |

| Glass Processing | Grinding and Polishing Tools, Special-shaped Tools, Diamond Saw Blade, Core Drill Bit, Scratch Pen/Tools | |

| Civil Engineering Construction | Cutting and Scraping of Concrete (With or Without Steel Reinforcement) | Diamond Saw Blade, Scraping Groove Blade |

| Asphalt Cutting and Scraping | Diamond Saw Blade, Scraping Groove Blade | |

| Engineering Construction Drilling | Diamond Core Drill Bit | |

| Equipment Installation Punching | Diamond Core Drill Bit | |

| Demolition of Buildings | Diamond Wire Saw, Diamond Saw Blade with Big Size | |

| Metal Processing | Processing of Semiconductor Silicon and Germanium | Precision Circular Saw Blade, Precision Polishing Disc, Precision Grinding Wheel, Micro Drill Bit, CVD Film Cutting Tool |

| Processing of Aluminum Alloys, Magnesium Alloys, etc | Cutting Tools, Grinding Wheels, and Honing Blocks for Turning, Boring, and Planing Composite Sheets(PDC) and Polycrystalline Materials(PCD) | |

| Drawing of Copper Alloys and Even Stainless Steel | Drawing dies made of PDC, PCD, and CVD | |

| Hard Alloy Processing | Processing of Hard Alloys (Including Steel Bonded Hard Alloys) | Grinding and Polishing Tools, Drill Bits |

| Wood and Composite Wood Processing | Wood Processing | Diamond Circular Saw Blades, Special-shaped Tools |

| Composite Wood Processing | Mortise and Tenon Forming Tool | |

| Processing of other special materials | Ceramic Processing | Grinding and Polishing Tools, Drill Bits |

| Refractory Material Processing | Diamond Circular Saw Blade, Drill Bit | |

| Hard Magnetic Processing | Grinding and Polishing Tools, Drill Bits | |

| Graphite Processing | Diamond Circular Saw Blade, Drill Bit | |

| Carbon Composite Material Processing | Diamond Circular Saw Blade, Drill Bit | |

| Application of Diamond Characteristics | High Hardness Components | Pressure Head and Cushion of Mould |

| High Thermal Conductivity Components | Electronic Device Heat Dissipation Components | |

| High Transmittance Components | Optical Window | |

| Large Particle Single Crystal | Decorative Components | |