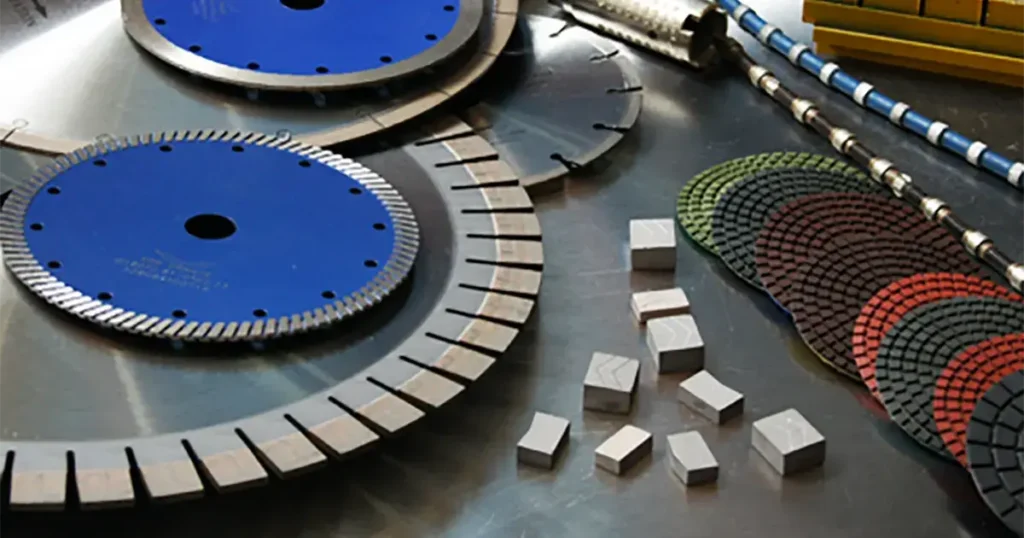

Sintering, vacuum brazing, and electroplating are the most used manufacturing technologies for the segment of diamond tools, which also differ in appearance, performance, and application. However, many users sometimes cannot distinguish them, even though they have rich experience in diamond tools.

Most diamond tools include diamond saw blades, core drill bits, wire saws, grinding tools, abrasives, etc., which are mostly produced using these three technologies. Diawe Tools provides a detailed introduction here to help customers better understand the diamond tools produced by these three technologies.

What are Sintered Diamond Tools

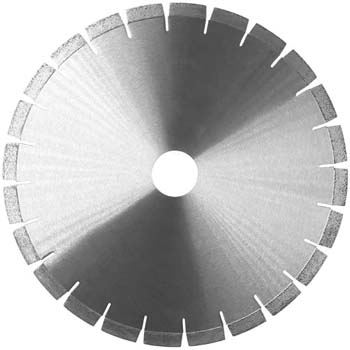

The sintered diamond tools are made by the mixed diamond powder and metal matrix powder, with high-temperature “hot pressing” sintering to form “segment” parts, then fixing the “segment” parts to the tool blank by laser welding, high-frequency welding, screw mechanical fixation, and other techniques.

Sintering is a metallurgical process. Under the conditions of high temperature and high pressure, atoms in metal powders can diffuse, chemical and physical reactions occur simultaneously, and the volume of the diamond “segment” shrinkage, reduced voids, and increased density of the entire diamond “segment”. Chemical bonds are formed between powders(metal-metal, metal-diamond), leading to particle bonding and recrystallization, resulting in better mechanical properties of the diamond “segment”.

However, excessively high temperatures can cause the metal powder to melt, and flow, and the diamond to carbonize, so the temperature during the sintering process should not be too high. Normally, it should not be higher than the melting point of the metal matrix.

Therefore, the control of temperature, pressure, and sintering time during diamond tool sintering has a significant impact on the quality of diamond tools. The matrix formula of the diamond tool working “segment” usually includes alloy powders such as iron, cobalt, nickel, copper, tungsten, etc. Sintering is usually carried out at a temperature close to but below the melting point of the matrix, so that the diamond powder is immersed in the semi-melted metal powder, but it will not cause uneven flow and distribution of the diamond due to complete melting. The melting point of these metal alloy powders is mostly above 900 ℃, so the temperature of 700 ℃ -900 ℃ and the pressure of 50MPa-70MPa are ideal temperature and pressure conditions during the sintering process.

The sintered diamond tools have a wider range of applications because the matrix has a stronger fastening force around diamond particles, better sharpness, and a longer lifespan, making them suitable for processing materials such as granite, marble, glass, porcelain, ceramic, plastic, and concrete.

Among them, for the processing of materials with high hardness, compared to brazed diamond tools and electroplated diamond tools, it has obvious advantages, such as granite. In terms of price, sintered diamond tools are also the highest.

Some sintered diamond tools:

What are Vacuum Brazed Diamond Tools

To make vacuum brazed diamond tools, it is necessary to use a vacuum brazing furnace. Diamond powder is mixed into the brazing material(such as nickel chromium compound), and the brazing material is heated to melt it. The diamond powder will dissolve in the liquid brazing material and then flow, spread, fill and diffuse on the substrate of the blanks of diamond tools. After cooling, a solid brazing layer is formed. A vacuum environment can prevent oxidation and corrosion of heated metal surfaces, and vacuum brazing doesn’t need the flux, resulting in diamond tools with smooth and beautiful surfaces.

We have discussed before that vacuum brazing is a relatively new technology for manufacturing diamond tools. The vacuum brazed diamond tools have good wear & grinding resistance, which are suitable for processing concrete and soft stones such as marble and limestone. However, its diamond is fixed mechanically, unlike sintered diamond tools, which use both mechanical and chemical fixation. The matrix has a weaker grip around the diamond, so for materials with higher hardness, such as granite, vacuum brazed diamond tools perform worse than sintered diamond tools.

The vacuum brazed diamond tools have the following advantages.

- The low heating temperature of vacuum brazing has little effect on the mechanical properties of diamond tools.

- Diamond exposure can reach 2/3, with high sharpness and good cooling effect.

- The deformation of the brazed parts is relatively small, especially when using the uniform heating (such as vacuum brazing furnace) brazing method, the deformation of the welded parts can be reduced to the lowest extent, and the precision of product dimensions can be improved.

- High production efficiency, multiple diamond tools can be brazed simultaneously.

Some vacuum brazed diamond tools:

What are Electroplated Diamond Tools

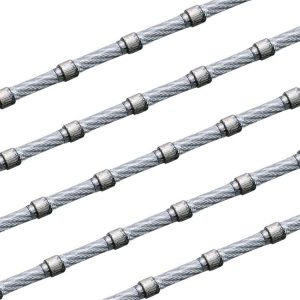

When manufacturing electroplated diamond tools, the substrate/blank of the tool is placed on the cathode, and the metal powder and diamond powder are placed on the anode. Under the action of electric current, the metal ions of the anode are attracted to the cathode and form a viscous metal layer on the cathode, in which the diamond is also embedded. Due to the working layer formed by electroplating is thin and service life is short, multi-layer electroplating is now widely used to produce diamond tools.

The main parameters of electroplated diamond tools include electrolyte composition, electric current flow rate, temperature, and electroplating time. Among them, electrolyte has a relatively large impact on environmental pollution. With the promotion of ESG environmental protection production, electroplated diamond tools are gradually being phased out.

In terms of product performance, the diamond is completely exposed and has high sharpness, making it very suitable for precision machining. Due to the weaker fastening force of the electroplating layer on the diamond compared to sintering and vacuum brazing, the diamond is prone to detachment and has a relatively shorter service life. Electroplated diamond tools are suitable for precision machining of automobiles or processing of soft stones such as marble.

Some electroplated diamond tools:

Conclusion

Overall, the three manufacturing processes of sintering, vacuum brazing, and electroplating have their own advantages and disadvantages. According to market feedback, sintered diamond tools and vacuum brazed diamond tools are the most widely used products now, while electroplated diamond tools are gradually being phased out and only used for processing some special materials, for example, some quarries use electroplated wire saw to cutting marble. Following are the main differences between the three technologies.

| Types of Diamond Tools | Working Object | Structural Deformation | Working Condition | Working R.P.M | Sharpness | Service Life | Product Price |

|---|---|---|---|---|---|---|---|

| Sintered Diamond Tools | Granite Quartz Marble Dekton Concrete Ceramic Porcelain Metal Agglomerates |

Yes | Dry/Wet | High | Good | Excellent | Higher |

| Vacuum Brazed Diamond Tools | Granite(Soft Type) Marble Concrete Ceramic Metal |

No | Dry/Wet | Hign/Low | Good | Good | Normal |

| Electroplated Diamond Tools | Marble Limestone Softstone |

No | Wet | High | Excellent | Normal | Cheap |

For the stone processing industry, we usually recommend sintered diamond tools for processing granite, and brazed diamond tools for processing marble. If grinding is involved, electroplated diamond tools can be used appropriately.