What is Diamond Gang Saw

Diamond gang saw, also known as diamond frame gang saw, is the tool that cuts stone through reciprocating motion. Usually used for cutting soft stone blocks such as marble. Because the stone is relatively soft and requires less cutting pressure, it is designed in a strip shape, and multiple saw blades can be used as a group to cut together to reach high cutting speed.

The diamond gang saw is equipped in the gang saw machine. The gang saw machine mainly comprises a saw frame, chain belt, column frame, gang saw blades and other components. The gang saw blade includes a metal blank and diamond segments. The earliest gang saw blades were made with steel bars and sand, therefore some people also call it as hacksaw.

The current development trend of stone processing is automation, high efficiency, and large-scale production, one set of diamond gang saws can reach a quantity of 120 pieces, and only one time machine assembly is needed to complete the cutting of the entire marble block.

Diamond gang saw is a diamond tool specifically used to cut marble blocks into thin marble slabs.

Advantages of Diamond Gang Saw

In the past, stone factories used large diamond saw blades and diamond sand saws to cut marble blocks into marble slabs. The size of marble slabs that be processed by large-diameter diamond saw blades is smaller than the radius of diamond saw blades, and the energy consumption and processing efficiency are very low. Using diamond sand saws, the surface quality of marble slabs is bad, cutting efficiency is low, material yield is low, and pollution is terrible.

The advantage of diamond gang saws is that they can process large-sized marble slabs with high surface quality and yield. As well as high processing efficiency, according to the size and processing requirements of the marble block, diamond gang saws of 80, 90, 100, and 120 pieces can be used as a group for simultaneous cutting. The production capacity can be between 25-45㎡/hour, with less waste of marble block, simple machine operation, and low requirements for working environment and worker skills.

The major stone processing countries in the world, such as Italy, India, Spain, etc., currently commonly use diamond gang saws to process marble slabs, and their manufacturing technology and product quality are in a leading position internationally. China has rapidly developed diamond gang saw technology through the introduction of foreign technology and equipment, as well as collaborative and independent innovation projects, and has also taken a leading international position.

Overall, diamond gang saw has the following advantages:

- High production efficiency: diamond gang saw can cut many stone slabs at once, greatly improving production volume compared to other cutting tools/equipment.

- High precision cutting: the synchronous movement of the blank of the diamond gang saw ensures a consistent thickness of the stone slabs, thereby achieving uniformity and high-quality stone cutting surfaces.

- Economic and environmental protection: by fully utilizing stone blocks, improving product yield, and reducing waste of stone blocks, the diamond gang saw optimizes resource utilization.

- Easy maintenance: the diamond gang saw machine has a sturdy structure that minimizes downtime and ensures reliable operation. Regular maintenance and replacement of diamond gang saws are also very convenient.

Application Classification of Diamond Gang Saw

Usually, diamond gang saw is used to cut marble, but with the improvement of mechanical equipment and diamond segment formulas, diamond gang saw has also emerged for cutting granite, artificial quartz stone, sandstone.

Diamond Gang Saw for Marble Cutting

Marble has a relatively soft hardness and is often cut using diamond gang saws. The high-precision diamond gang saws and synchronized cutting of multiple blanks ensure a smooth cutting surface for marble. The marble slabs cut by diamond gang saws have a good texture and high aesthetic appeal, and are suitable for countertops, walls, decorative surfaces, background walls, etc.

Diamond Gang Saw for Granite Cutting

The diamond gang saw used for cutting granite requires very high hardness and durability, and the equipment needs to have a sturdy structure. The fixation of the blanks should be very firm. Granite slabs cut from diamond gang saw have a consistent thickness and smooth surface, making them a high-end granite product that can be used for kitchen countertops, building exterior hanging walls, plazas, and more.

Diamond Gang Saw for Artificial Quartz Stone

Artificial quartz stone is a non-natural stone material made from over 90% natural quartz and about 10% colorants, resins, and other additives that regulate bonding, curing, and other properties. For the convenience of manufacturing, artificial quartz stone is first made into large raw materials similar to natural stone blocks, and then cut and processed. Artificial quartz stone has high hardness and density, so using diamond gang saw for cutting requires equipment with high rigidity. The artificial quartz slabs cut by diamond gang saws are suitable for use in countertops in kitchens and bathrooms, wall decorations, shopping mall walls, etc.

Diamond Gang Saw for Sandstone

Sandstone is a sedimentary rock mainly composed of various sand particles cemented together, with particle diameters ranging from 0.05-2mm and sand content greater than 50%. Therefore, when using diamond gang saws to cut sandstone, the requirement of grindability of diamond segments is very high. Sandstone slabs cut by diamond gang saw can be used for interior and exterior wall decoration, flooring, door frames, window frames, furniture, railings, tombstones, etc.

What are the Parts of Diamond Gang Saw

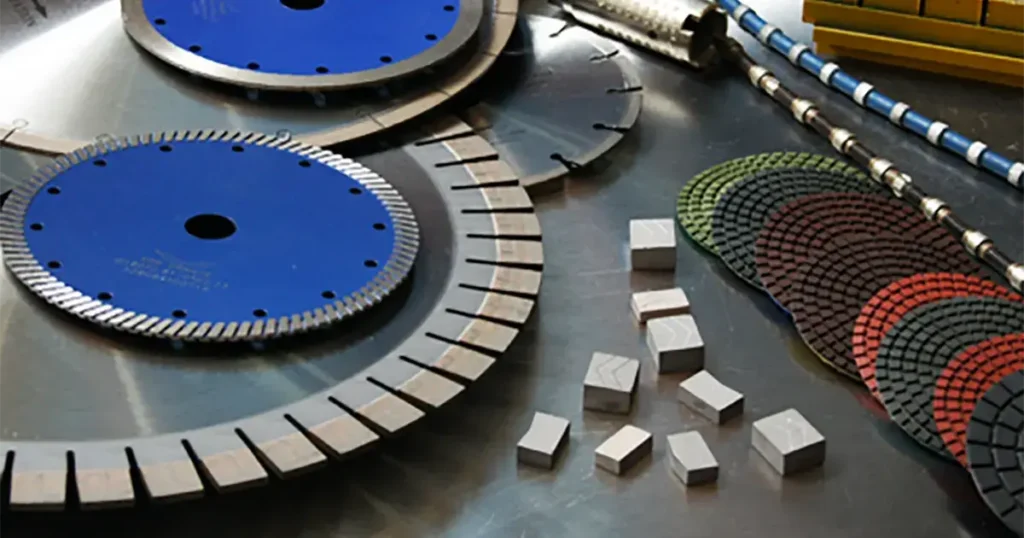

A complete diamond gang saw includes blank, diamond segments, and fixed buckets and mentioned. The most important are blank and diamond segments.

Blank of Diamond Gang Saw

Blank is the main part of the diamond gang saw, used to fix diamond segments. During the high-speed reciprocating cutting of stone by diamond gang saw, it is required that the blank be stable, durable, have high fatigue resistance, and not easily deformed.

The tensile strength of the blank should be (1400 ± 80) MPa, and its hardness should reach 42-44HRC during bright quenching. It has effective thermal conductivity and can reduce the possibility of martensite formation due to overheating when welding the diamond segments. The perfect diamond segment edge treatment ensures a strong bond between the diamond segments and the blank.

Diamond Segments of Diamond Gang Saw

As mentioned above, the diamond gang saws are mainly used for cutting marble, granite, artificial quartz, sandstone, etc. The design, size, and structure of diamond segments vary depending on the cutting object and usage conditions.

- Diamond segments of diamond gang saw for marble cutting: mainly used for cutting Indian green, large flower green, dark emperador, various beige marble and white marble. Some marble has holes that can easily trap diamond segments, causing them to be impacted. Therefore, diamond segments are often designed as circular arcs or double trapezoids to increase the welding length of diamond segments, reduce the impact force during operation, and avoid tool detachment.

- Diamond segments of diamond gang saw for sandstone cutting: mainly used for sawing various hardness and strong abrasive sandstones, such as Australian sandstone, Yunnan sandstone, Shanxi sandstone, etc. Diamond segments should have good wear/grinding resistance while ensuring sharpness. Commonly used diamond segment shapes include flat single-layer segments, flat sandwich segments, and trapezoidal sandwich segments.

Unlike diamond circular saws, diamond gang saws move back and forth while cutting stone. The diamond powder in the diamond segments does not have tadpole layer support, resulting in harsh force conditions. In addition, many blanks are assembled on the saw frame, and the spacing, parallelism, perpendicularity, and tension of the blanks must be adjusted. Therefore, there are many influencing factors, and the production process must be optimized to ensure the quality and efficiency of diamond gang saws.

Key Technologies of Diamond Gang Saw

Diawe Tools has over ten years of research and development experience in diamond gang saw. We have summarized the following key technologies that can improve the quality of diamond gang saw.

- The diamond surface coating improves the grip between the diamond and the matrix: practice has shown that coating titanium on the surface of the diamond or mixed coating(TiC+Ti-Cr+Ni) on the surface of the diamond can form chemical bonds with the metal matrix, reduce diamond detachment, increase useful working parts of the diamond, improve sawing efficiency, and extend service life.

- Reduction treatment of cold-pressed diamond segments before vacuum hot-pressing sintering: determine the reduction temperature and time for different matrix formulations to reduce oxygen content, create conditions for activated sintering, and improve the bonding strength between diamond and matrix.

- The sandwich multi-layer structure of diamond segments is adopted to create multiple free surfaces for breaking rocks and improving sawing efficiency. At the same time, the multi-layer structure is conducive to high-speed balanced sawing of diamond segments, which is not easy to produce skewness and swing.

- Diamond segments adopt a trapezoidal structure and inclined bottom water channel to reduce friction between diamond segments and the surface of the stone, which is beneficial for cooling, slag containment, and slag discharge.

- By using thin blanks and thin diamond segments, the width of the saw seam can be reduced, and the cutting efficiency and yield can be improved.

- Pay attention to on-site service of diamond gang saws: when installing diamond gang saws, pay attention to controlling and adjusting the verticality and parallelism of blanks, the concave curvature of saw blades, and adjusting tensile stress. Ensure the normal operation of the diamond gang saw to prevent issues such as misalignment, poor flatness of the board surface, and abnormal wear of diamond segments.