According to the structures and applications of the diamond wire saw, the length standard used for cutting is also different.

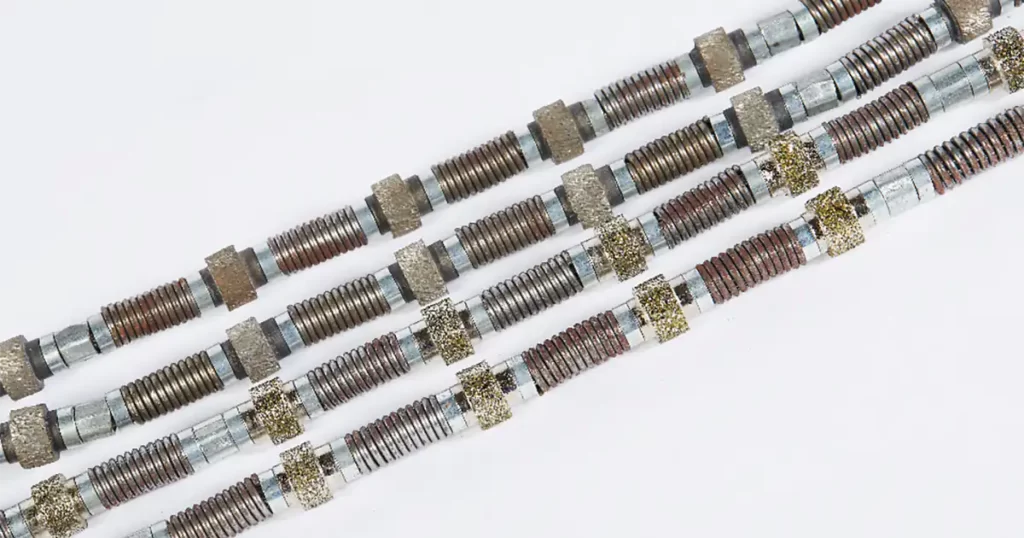

When mining soft stone, the full sawing mining process is usually adopted, from the large separation cutting of the mining separation body with a cutting area of 50~100m2 or a bigger cutting area to the separation body with a cutting area of 15~50m2. The cutting of stone blocks with a shaping surface of only 1.5~8m2, all of which are completed by the diamond wire saw. Therefore, the spring-type diamond wire saw is generally 5m, 10m, 15m or 20m as a unit length. Users can select the appropriate length of diamond wire saws according to their needs, or connect diamond wire saws with different lengths and basically the same outer diameter of the diamond beads to form the required service length.

When mining granite or other hard stones, the diamond wire saw is generally used to assist the cutting mining process. The diamond wire saw is only responsible for the separation and cutting of the large surface of the mining separation body, that is, to replace the cutting of the flame cutting machine. The disintegration of the separation body and the shaping of the waste material are completed by the combination of row hole drilling and controlled blasting or the splitting of cement expansion agent. Therefore, the area to be cut by the diamond wire saw is generally large, with the maximum of several hundred square meters, and the minimum of sometimes more than 50 meters. Therefore, the unit length of the plastic injection or rubber injection diamond wire saw is usually 30 meters, 50 meters, or longer. Although the diamond wire saw with a short length unit can also be produced in the factory, too many joints/connector of diamond wire saw will also affect the best performance of the bead rope.

The length of the diamond wire saw is usually unlimited. After it is wrapped around the cutting surface of the stone, it is connected into a closed cutting ring with a joint. However, when using the diamond multi-wire saw, the length of each wire rope should be as consistent as possible to improve the accuracy of the tension system. Therefore, when producing diamond multi-wire saw in the manufacturing plant, it is generally made into a closed structure without joints, which not only ensures the consistency of the length of each diamond wire saw but also ensures the quality of preloading before the use, so as to minimize the wear of each diamond wire saw.